MEDIUM SHEAR MIXING

The Infini-Mix “S” series mixer is the work-horse of the Infini-Mix™ Liquid-Liquid product offering and ideal for medium-shear mixing applications. Quite simply, this mixer has no equal!

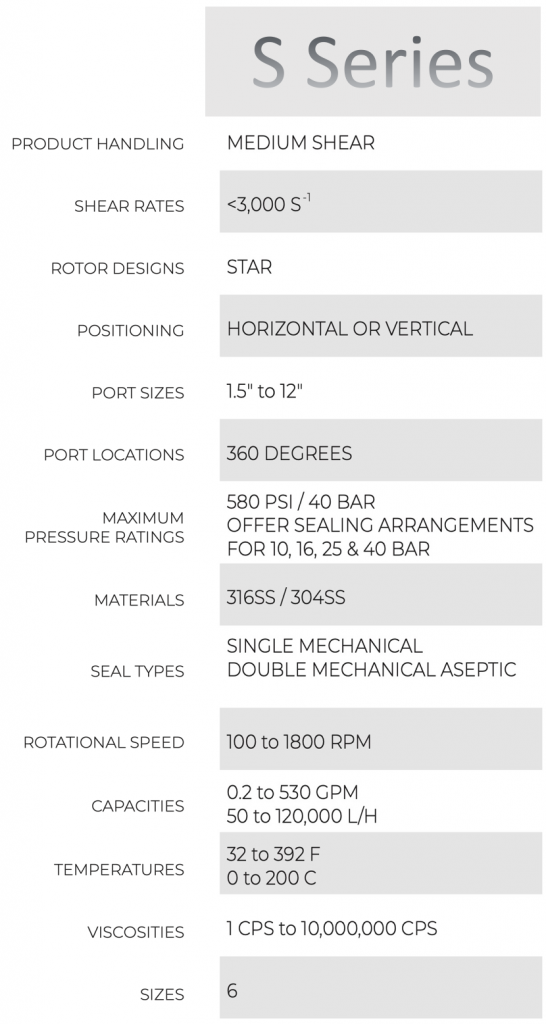

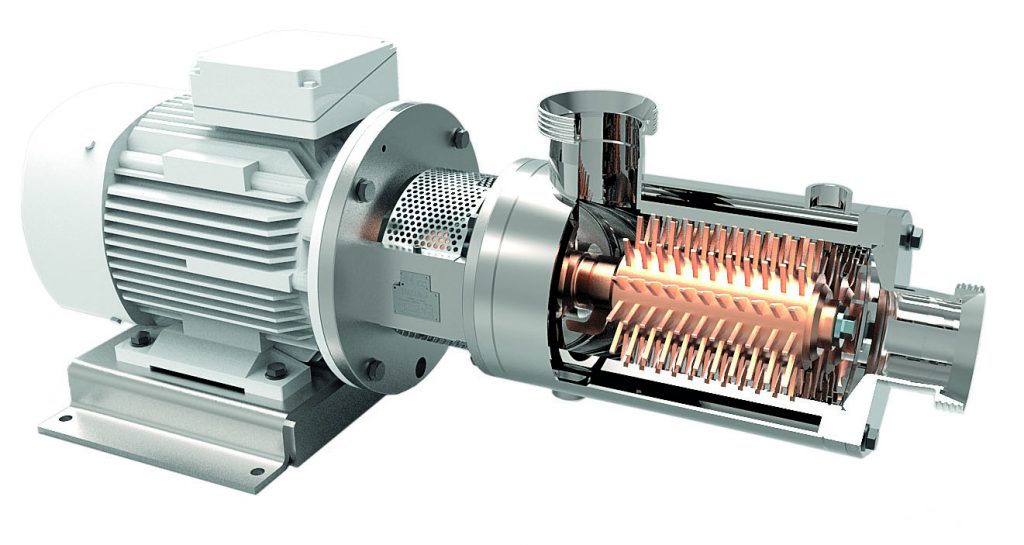

While most of our competitors would consider this mixer “high shear”, we classify the “S” series mixer as a “medium shear” mixer. The combination of the multiple stages of mixing elements running at speeds up to 1800 RPMs produces a far more consistent result than what others consider “high shear.”

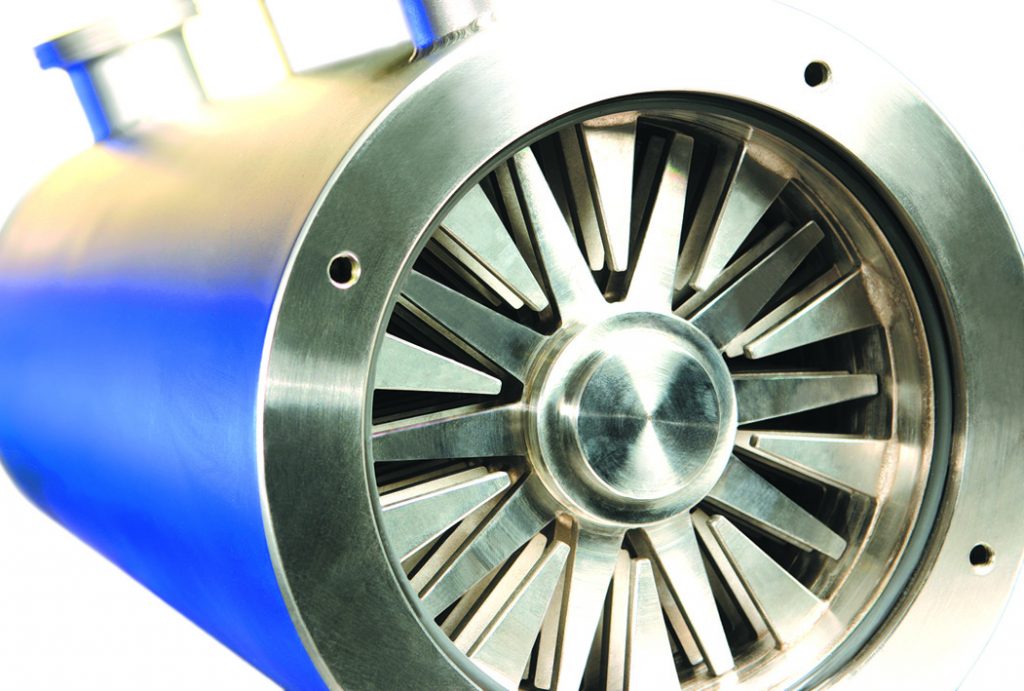

Characterized by star-shaped mixing elements on the rotor and stator, the “S” series mixer is capable of receiving multiple ingredient streams simultaneously and handling viscosities up to 10,000,000 cps. Additionally, all “S” series mixers come standard with a jacketed housing for heating or cooling the product. This unit is also available with a temperature controlled rotor for precise temperature control.

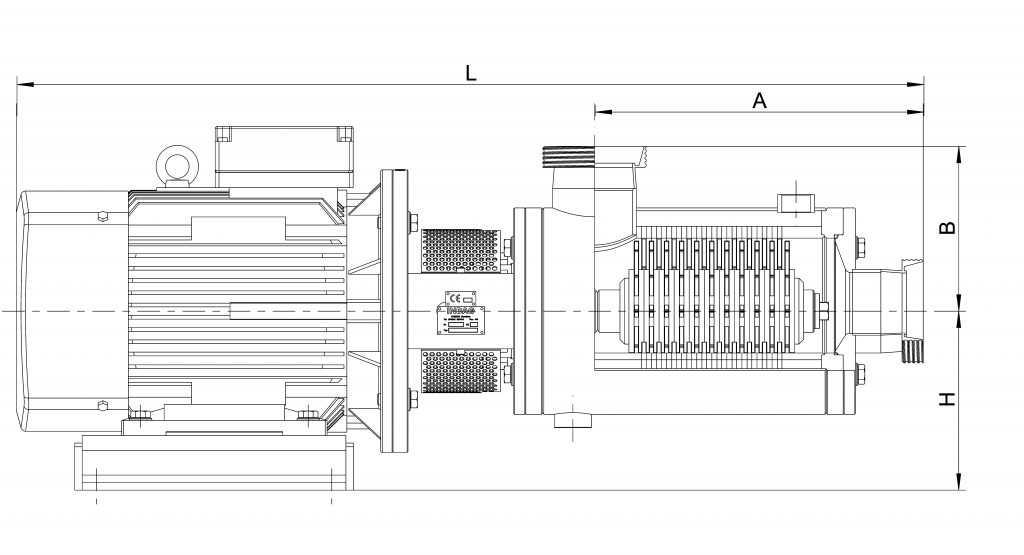

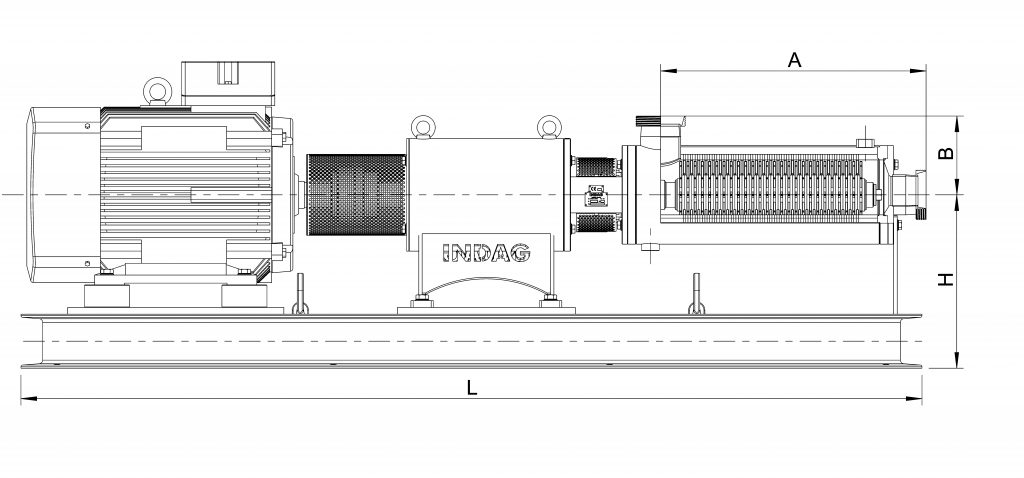

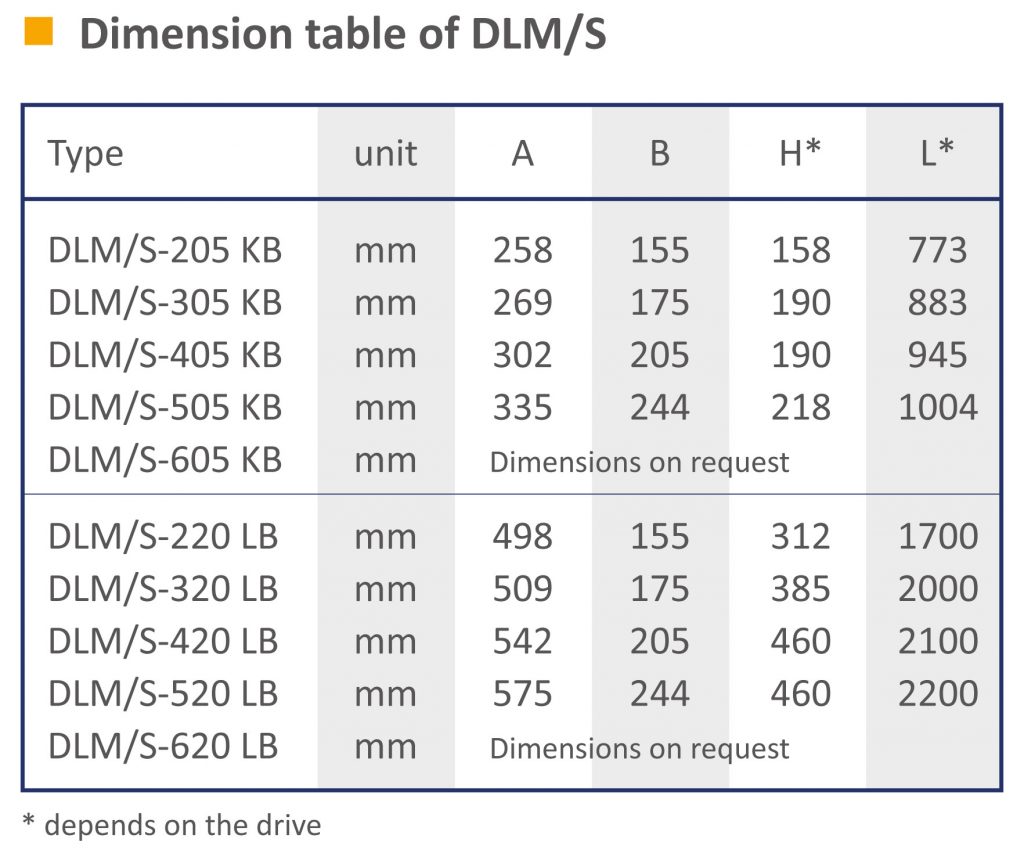

The “S” Series mixer can be installed horizontally or vertically and adapted to be “free-draining” in any orientation. The low volume design means less product loss when changing over recipes.

The “S” mixer is also capable of withstanding process pressure in excess of 500 PSI and temperatures up to 400ºF.

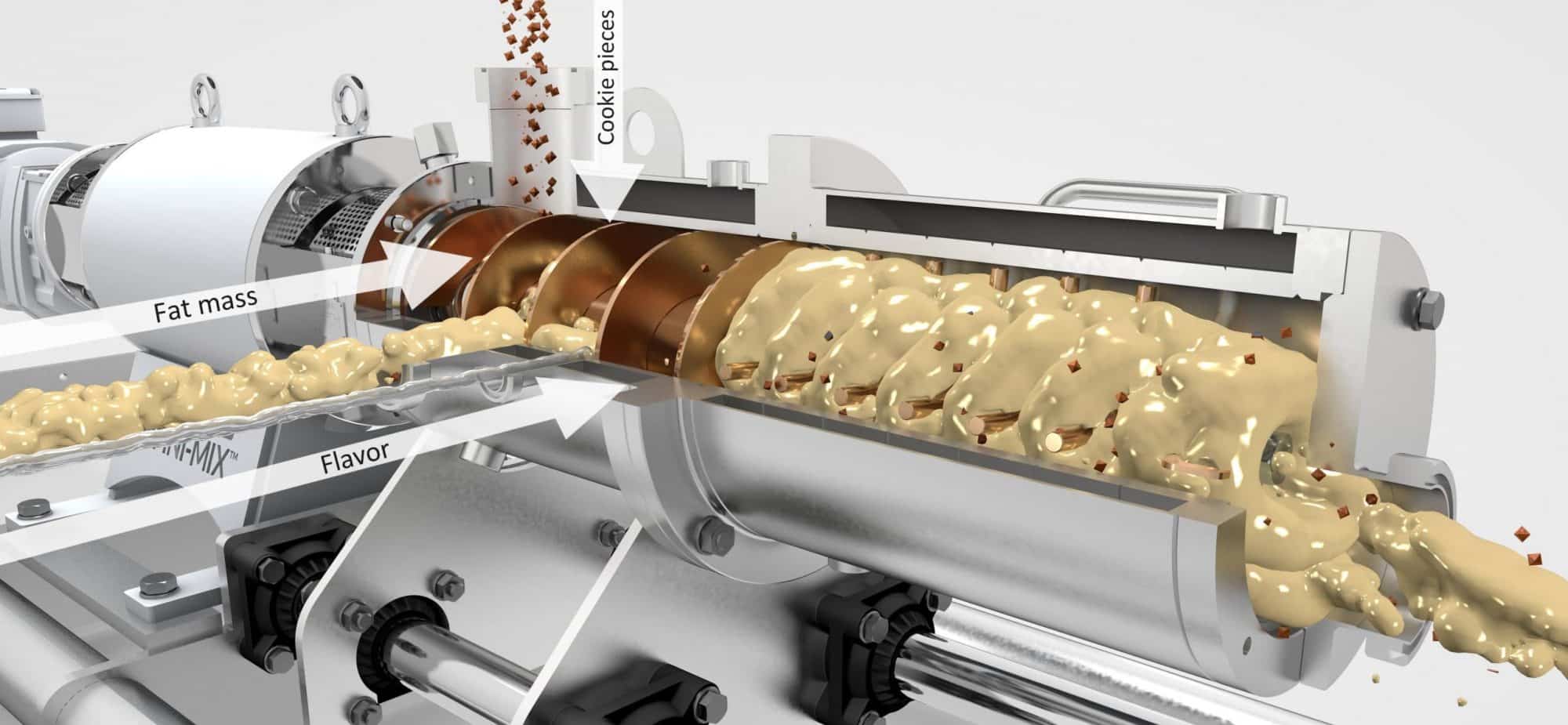

We commonly use progressive cavity pumps in chemical and environmental applications while focusing on twin screw pumps in hygienic applications. These types of pumps have high suction and discharge capability and deliver non-pulsing flow to the mixer. These ingredient streams are accurate and highly repeatable which make it ideal for continuous inline medium shear mixing applications.

This Mixer Has No Equal!

Aside from the high pressure, high viscosity and high temperature capabilities, the S-series mixer STILL HAS NO EQUAL!

This mixer is commonly used for LIQUID-GAS mixing. Inject steam with your emulsion and allow the mixing elements to fully disperse the steam to cook the product. 100% of the steam condenses which means all thermal energy is used.

Inject CO2 into a marshmallow paste or nitrogen into a peanut butter. The S mixer is ideal for product aeration.

Common MEDIUM Shear Mixing Applications

EXAMPLE

Molten sugar masses for products like hard candies and lollipops are extremely hot (300°F+) and heavily viscous. High amounts of citric acid, coloring and flavoring must be fully and evenly dispersed while maintaining high temperatures. Losing temperature during this stage can result in the candy hardening inside the mixer. The is a process nightmare!

The Infini-Mix™ S-Series mixer with our jacketed housing and temperature controlled rotor option disperse with tight temperature control. Our inline mixing solution is far more energy efficient and simpler to clean on flavor changes than traditional batch process. The smaller footprint and reduction in labor costs is an added bonus!