LOW SHEAR MIXING

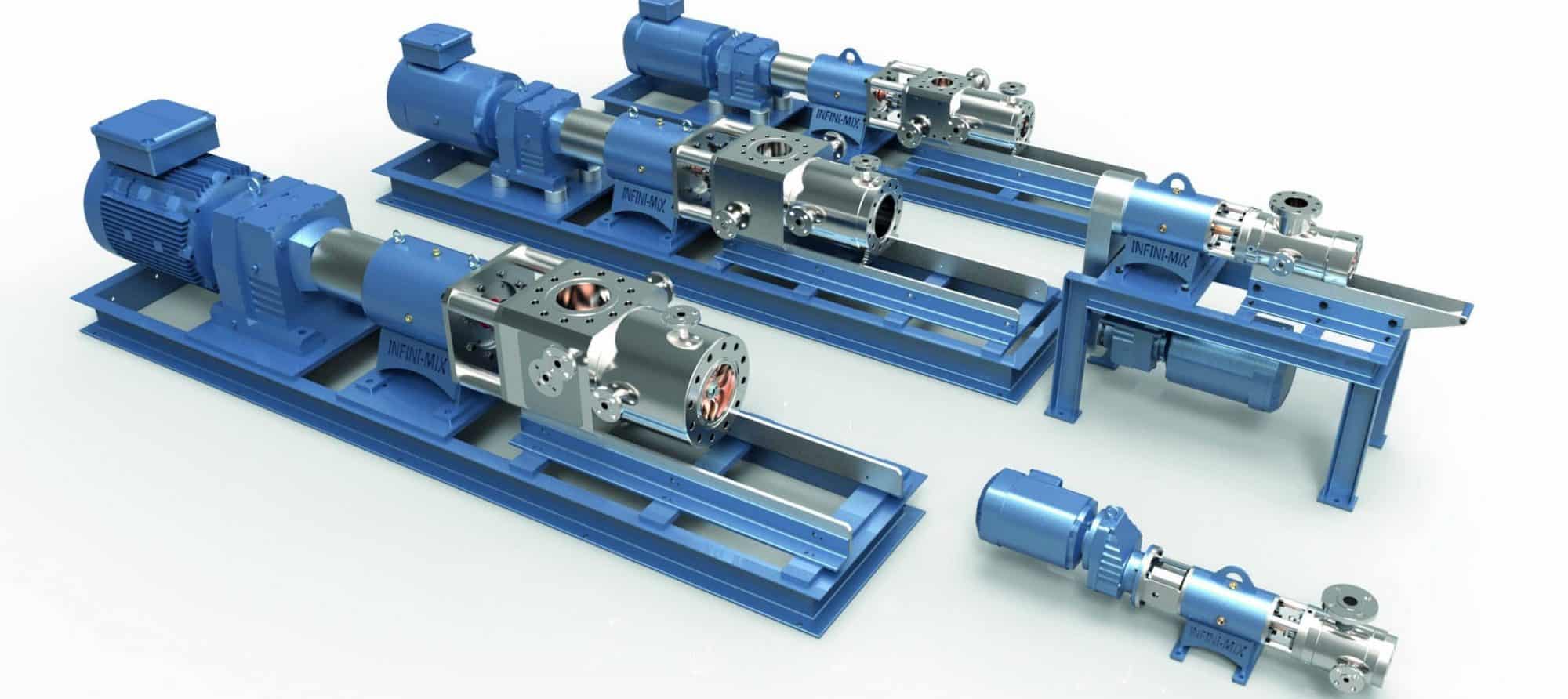

The INFINI-MIX "P" Series Mixer

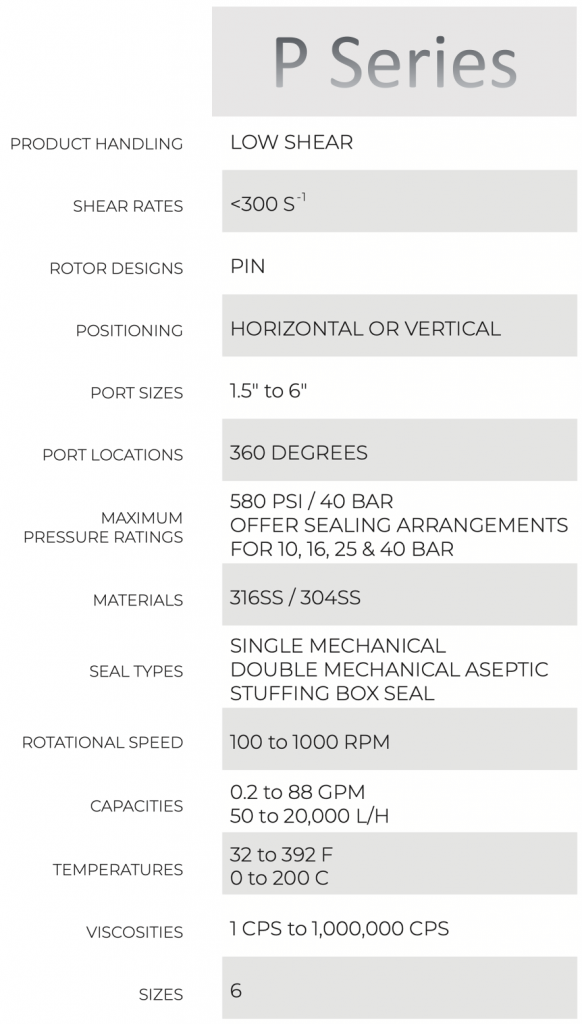

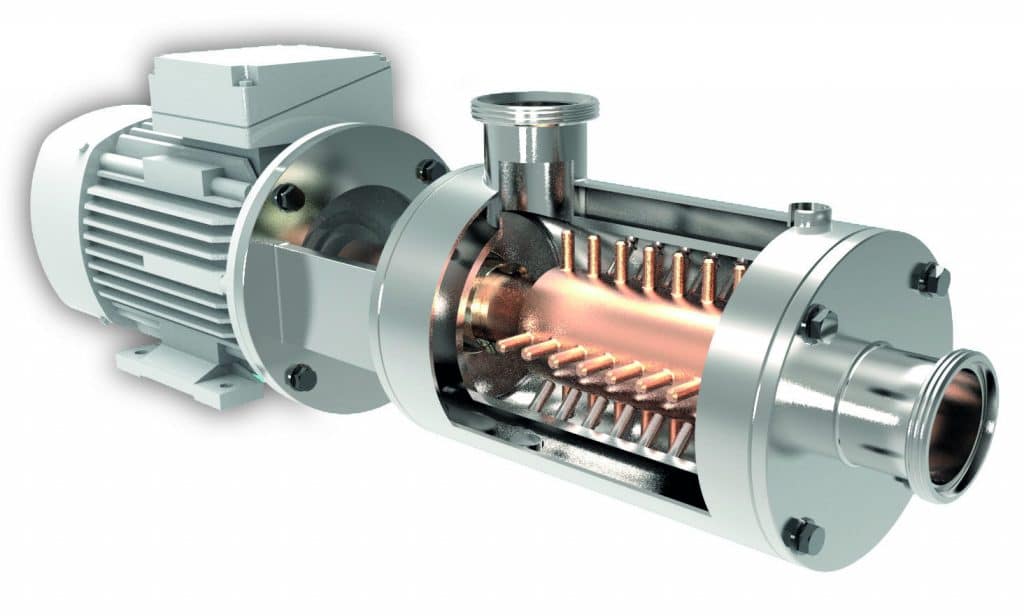

The Infini-Mix™ “P” Series Mixer is designed for delicate, low-shear mixing applications, typically for heavier and more viscous products like blending honey into peanut butter. It is designed with round, “pin-shaped” mixing elements without any sharp edges. The spacing between the mixing elements is based on the application and what size particulates you may want to maintain.

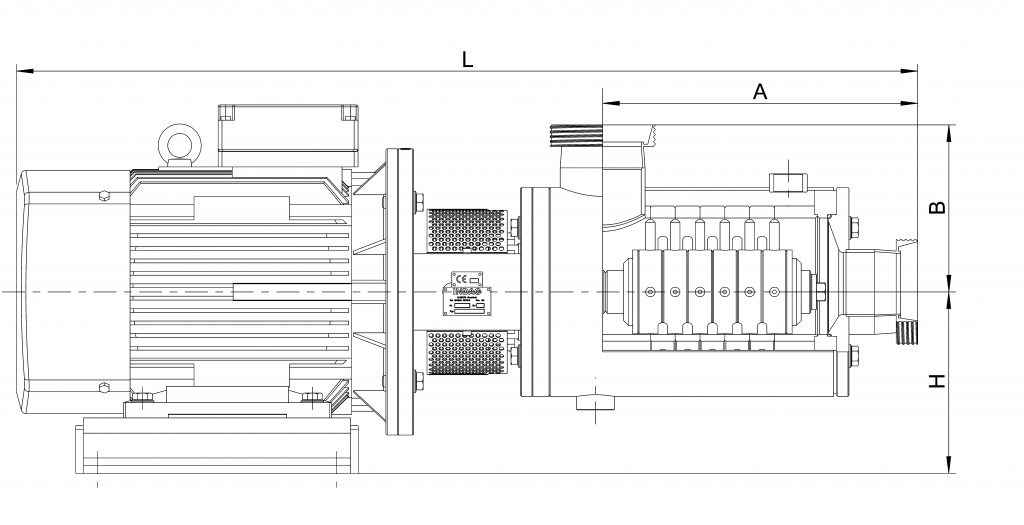

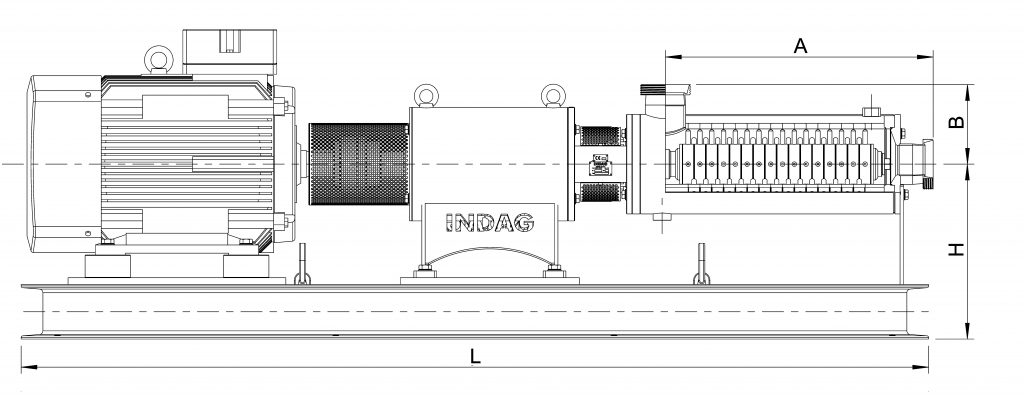

The “P” Series mixer is a low rotational speed mixer with speeds not exceeding 1000 RPMs. Typically mixers are installed horizontally, but can be adapted to be installed vertically to save space.

Additionally, the low volume design translates into less product loss when changing over recipes. They can be adapted to be “free-draining” in any orientation.

The low shear of the “P” series mixer is complimented by the delicate handling of the pumps that are used. We commonly use twin screw pumps. These types of pumps deliver a smooth, non-pulsing flow to the mixer ensuring accuracy and product integrity. The mixers and the pumps can be configured to pass solids in excess of 2″ diameter.

Dynamic vs. Static Alternatives

The P series mixer is a common alternative to static mixers. With high viscosity liquids, a static mixer can high high pressure drops, they can clog with large particulates and they are difficult to clean. Conversely, the Dynamic Mixer will have little to no pressure drop while protecting delicate soft solids. They also generate the turbulence inside the mixer during CIP so they are fully CIP-able. Above all, the ability to vary the speed across a wide range makes the P series mixer an easy choice for low-shear mixing applications.

EXAMPLE

In a lotion application where delicate, low shear mixing is required, two liquid streams are pumped to the mixer. Base lotion and a differentiating fragrance are metered directly into the P series mixer. The mixer is installed directly above the depositor. When production calls for a product change, simply swap the fragrance line feeding the mixer and clean from the mixer forward to the filler bowl and you are on to the next skew.

This process can be further simplified with a small mix proof valve manifold for the various additives that would be used.

Similarly, this method is used for a wide variety of differentiating additives. Fragrances, active ingredients like CBD oil and inclusions like exfoliating beads are all commonly used and delicately blended into lotions with the “P” series mixing elements. There is no need to clean the process lines or any batch tanks. This is a tremendous cost savings when downtime and cleaning costs are drastically reduced.