DELI SALADS

The Infini-MixerTM Solid-Liquid mixer was designed for the delicate handling of soft solids in a continuous process. Most deli salads like potato salads, cole slaw and pasta salads have all traditionally been made in small batches with ribbon blenders. All of the liquid and solid ingredients are pre-weighed and hand fed into the blender. Once the batch is finished, the ribbon blender pushes the product into a small tote which is then wheeled to a “dumper”. The dumper lifts the tote and dumps the finished product into the depositor. Pumps are rarely, if ever, used. This ensures the customer maintains the highest level of product integrity.

The Problem

This is an extremely labor intensive process making batch after batch by hand.

More batches translate to less consistent product.

It is very costly to continually wash each tote in-between batches.

Lift & dump stations are costly to implement and maintain

The Solution

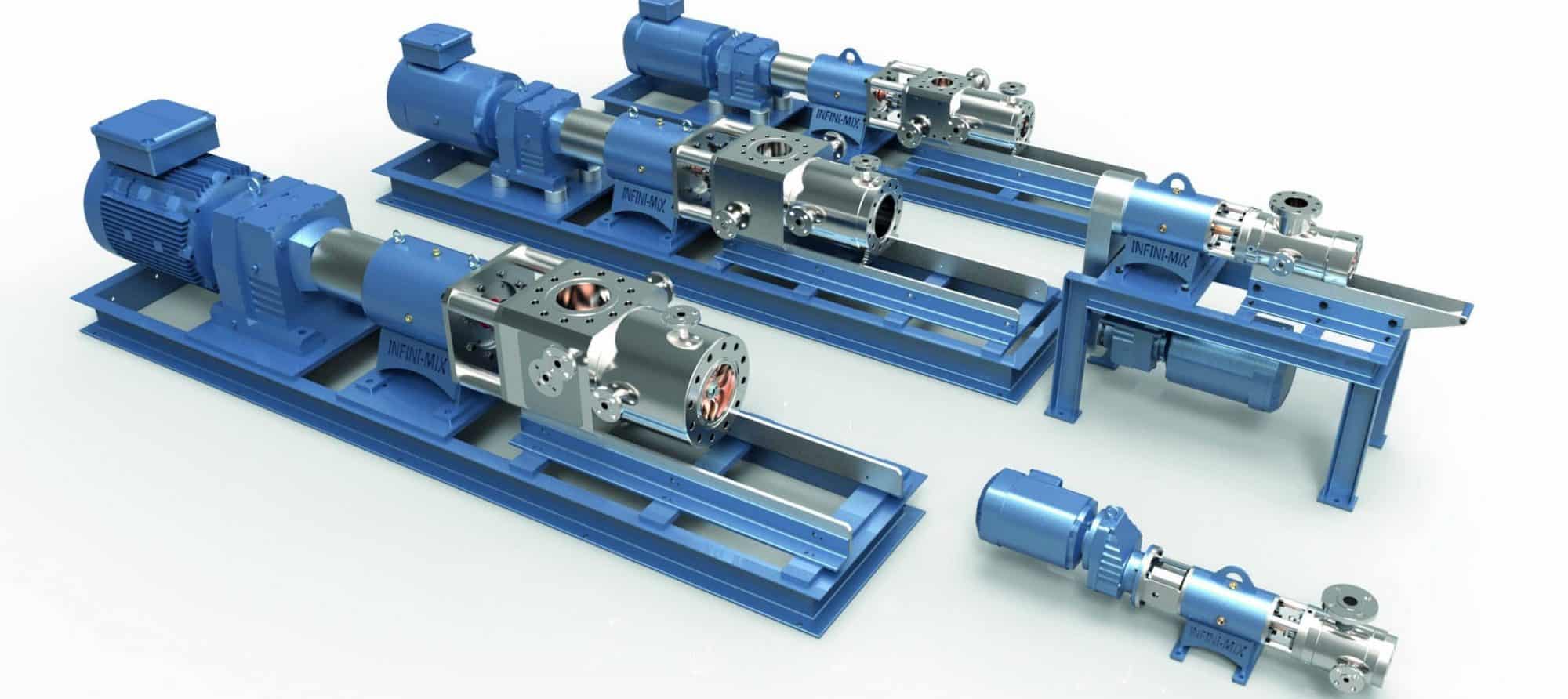

The Infini-MixerTM is installed over the depositor. The soft solids are delicately metered directly into the Infini-MixerTM with a weigh-belt feeder. All liquids are metered directly into the mixer with pump and a flowmeter. Any additional solid ingredient streams (spice blends, shaved carrots, scallions, etc.) are metered directly into the Infini-MixerTM with a gravimetric, loss in weight solids feeder.

The Infini-MixerTM continuously blends the various ingredient streams at the appropriate ratios. The finished, blended product discharges from the Infini-MixerTM directly into the depositor.

When production calls for a recipe change, the mixer can easily be cleaned in place or flushed for a similar product. Ingredient ratios are easily changed by using a PLC to control the system.

Most importantly, the mixer’s delicate handling of the soft solids gives manufacturers the peace of mind knowing that STILL no pump ever touched their primary ingredient.