FLAVORING BEVERAGES

Flavoring beverages and concentrates is where INFINI-MIX offers the most economical solution. Typically, blending multiple flavorings DOES NOT REQUIRE HIGH SHEAR unless gums are involved.

All of our mixers are capable of receiving multiple liquid streams simultaneously. Allow INFINI-MIX to look at your application to offer the perfect solution. Why invest in a high shear mixer when a lower cost, less intensive inline mixer will do the job?

EXAMPLE #1

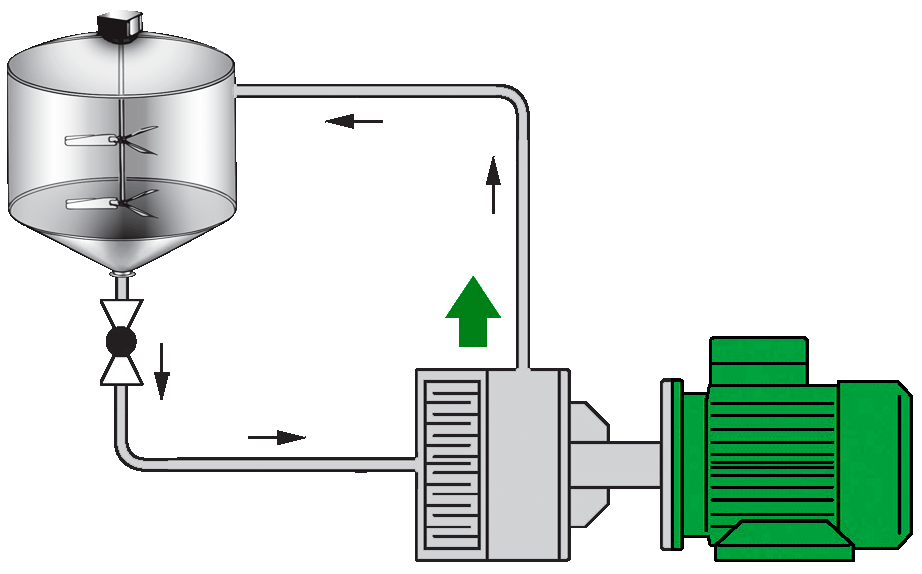

Adding Flavoring Powders to a Batch Process

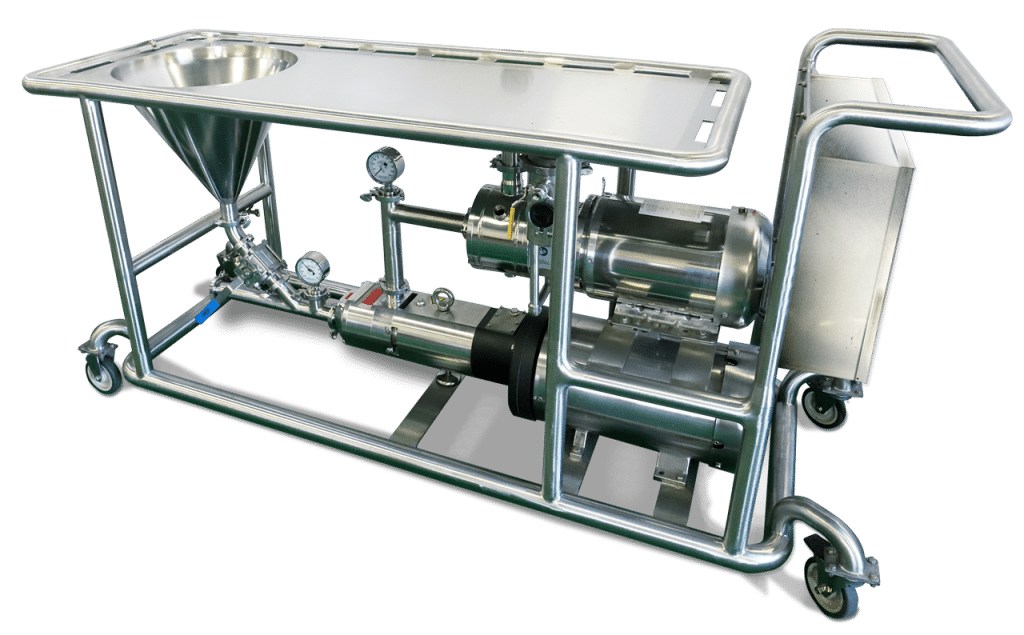

The Infini-MixTM RBM Powder Induction System can easily draw powders, emulsifiers and stabilizers into a liquid stream, regardless of the viscosity of the motive fluid. Utilizing the H series mixer on this system, you are guaranteed to fully hydrate all powders and eliminate any clumps or agglomerations.

The RBM System utilizes both twin screw and liquid ring pumping technologies to create the high suction for incorporating the powders as well as the high pressure capability to transfer the viscous liquids. This allows the RBM system to continue to incorporate powders into highly viscous flavor emulsions.

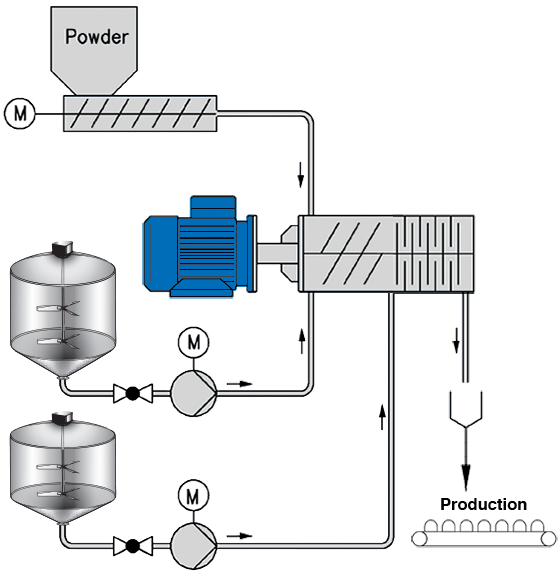

EXAMPLE #2

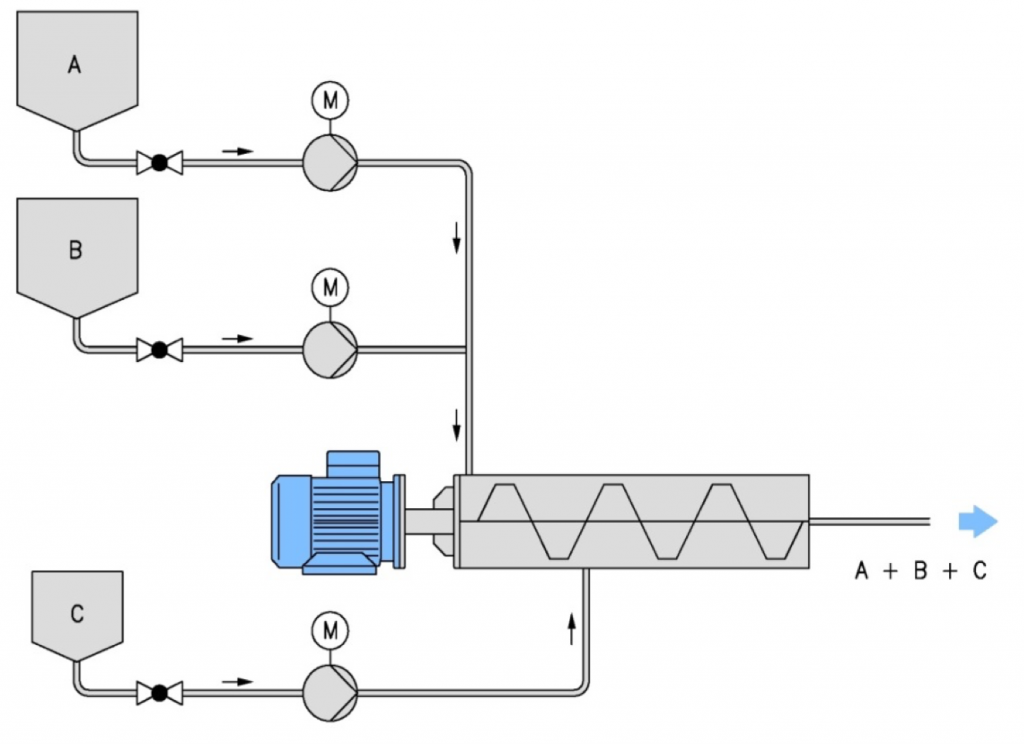

Continuous Blending Multiple Liquid Streams

A recent customer makes 6 flavors of seltzer. Each flavor drawn out of a tote and pumped into a batch and then transferred to the packaging line. The batch tanks and the process lines must all be cleaned before changing to the next flavor. This takes time from production and requires a full system flush which adds to their water consumption.

In changing to a continuous, single pass process, the customer uses a small metering pump to draw out of the tote of flavoring and injects the flavoring into the Infini-Mix N Series Mixer. A separate pump and flowmeter pump the base product to the mixer. The mixers sits at the end of the process, minimizing the piping and equipment that the flavoring comes into contact with. When the customer wants to switch flavors, they simply flush the piping from the mixer forward, switch the flavoring tote hook-ups and then they are on to the next recipe.

This works for juices, alcoholic beverages, soft drinks.