NON-CHOCOLATE CONFECTIONERY

HARD CANDY MANUFACTURING

Hard candy manufacturing requires blending a wide variety of colorings, flavorings and citric acid into molten sugar masses at very high temperatures. Infini-MixTM offers a full line of inline mixing solutions that are capable of handling temperatures in excess of 350°F. Coloring, flavoring and citric acid for mouth feel are all common hard candy additives that can be blending continuously into the molten candy mass.

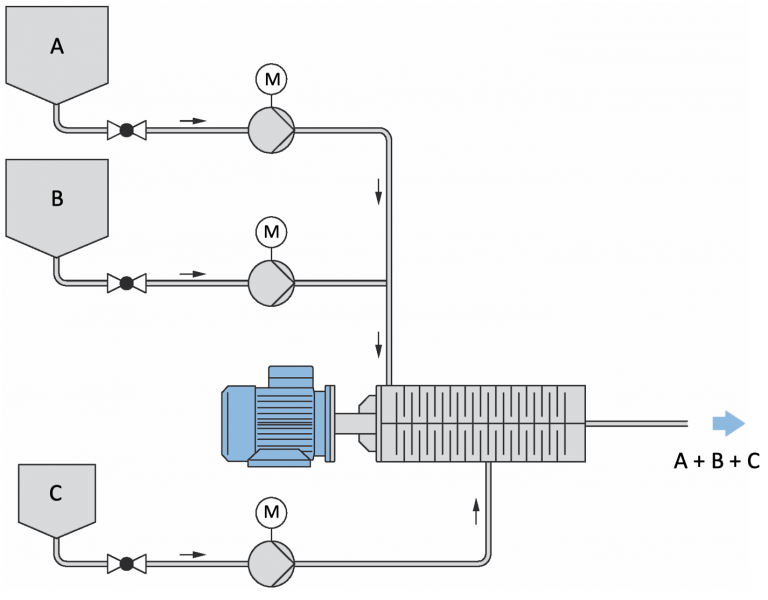

Many of these applications are more efficiently performed as Late Stage Differentiation, or End of Pipe, applications. This means adding the final differentiating ingredient, or set of ingredients, at the end of the process. For molten sugar masses, it is crucial that the high temperatures be maintained while these final additives are being blended inline. All of our mixers come standard with jacketed housings for heating (or cooling). We also offer a Temperature Controlled Rotor for difficult applications, like hard candies, where losing temperature can mean plugging up an entire process. Our mixers can be designed with multiple inlets to accept multiple ingredients streams simultaneously and still maintain tight temperature controls.

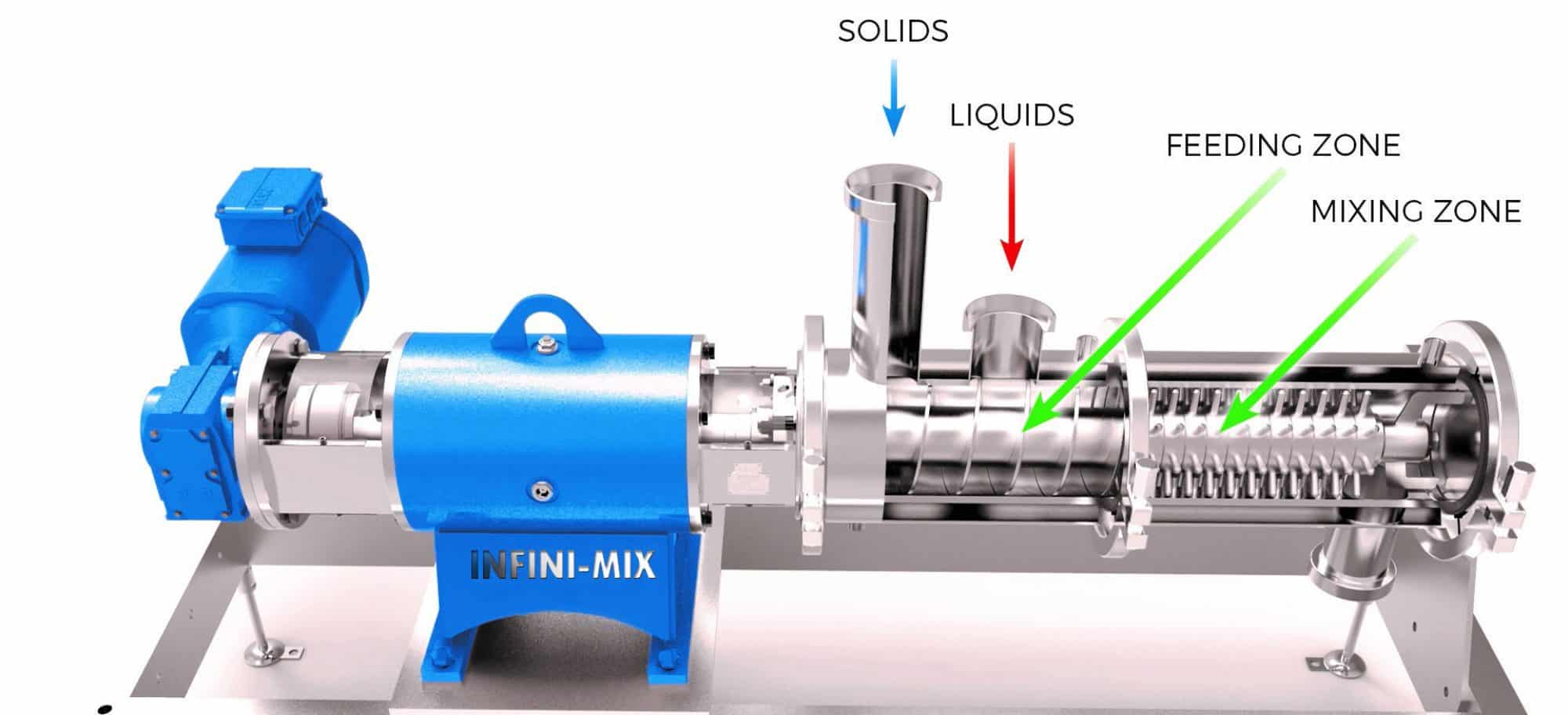

The Infini-MixTM S Series Liquid-Liquid Mixer is ideal for blending colorings and flavorings into molten sugar masses during the late stage differentiation process. The temperature controlled rotor option allows you to maintain tight temperature control on your product.

The Infini-MixerTM Continuous Solid-Liquid Mixer is commonly used for dosing calcium and citric acid into the molten sugar masses to give it the proper mouth feel and “bite” that many candies go for.