Twin Screw Pumps

Twin Screw Pumps are quickly gaining dominance as the positive displacement pumping technology of the future. Higher suction capability, higher speed capability, higher pressures, higher temperatures and low shear product transfer are all benefits of of the twin screw pump technology.

Why Is Twin Screw Technology Setting The Benchmark in Positive Displacement Technology?

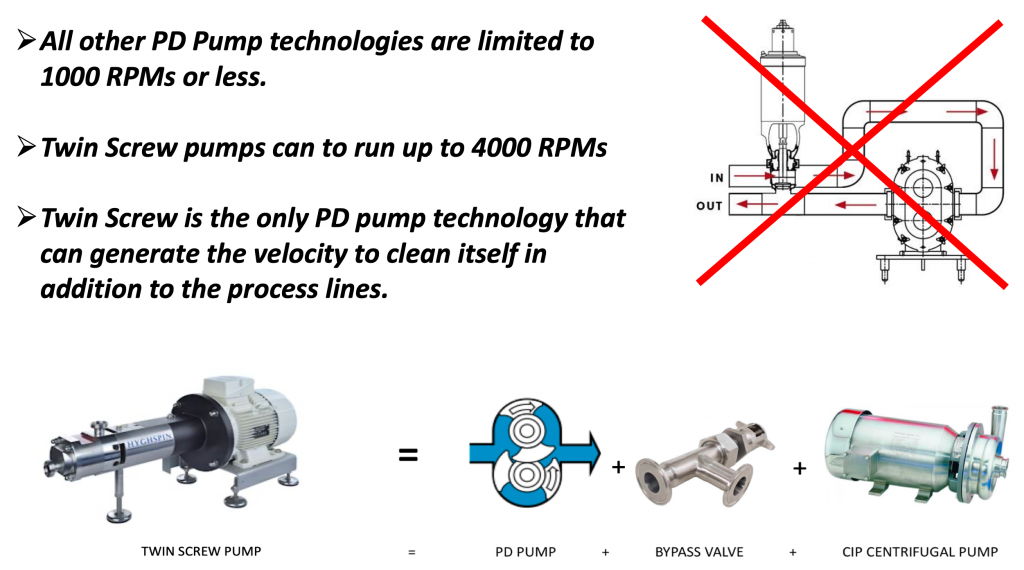

Most reasons for this growing preference are directly related to the speed capability. While most positive displacement pumps are limited to 600 – 1000 RPMs, most Twin Screw Pumps can run up to 4000 RPMs. What does that mean for you?

High Suction Capability

High suction capabilities allow our customers to completely evacuate their tanks resulting in higher yields. Most twin screw pumps can pull as close to full vacuum as possible, up to 28.25″Hg!

The video below is of an twin screw pump sucking finished mozzarella cheese. This is a semi-solid that does not flow. No other PD pump technology can withstand the intermittent product flow without pump damage.

Ability To Run Dry & Pump Air!

Twin screw technology is capable of pumping multiphase. It does not create air but it will pump up to 60% entrained air making it difficult to airlock!

Also, with the screws perfectly balanced, the pumps are able to run at full speed with no product and not cause any damage. A flush seal enables customer to run dry for hours.

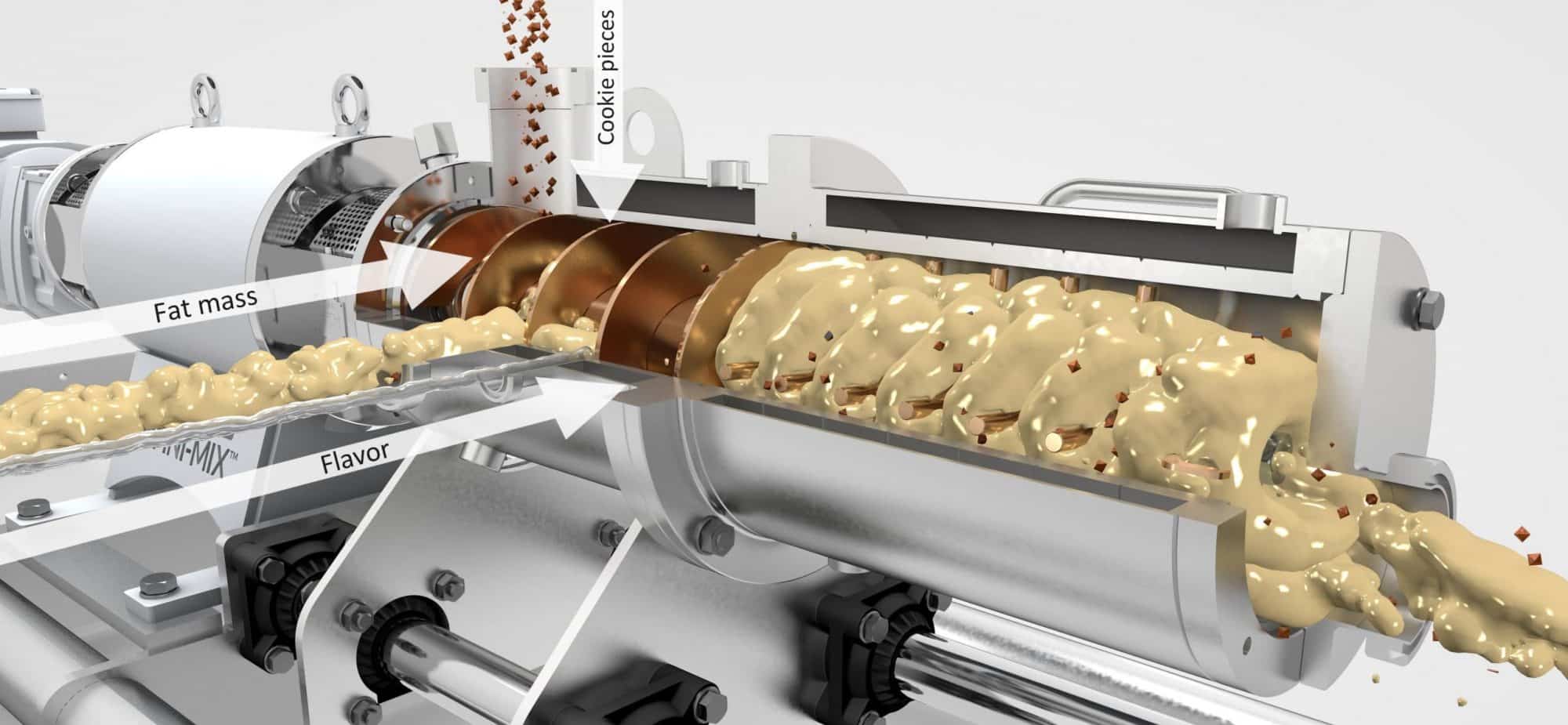

Low Shear Product Handling

As product enters a the pump, it moves through the pump in an “axial flow” with little turbulence. This imparts far less shear than traditional circumferential piston and lobe style pumps.

Additionally, with each size pump we offer up to 8 different screw pitches. Wider screw pitches enable us to pass large soft solids. Our largest pump can pass delicate solids in excess of 2.5″ in diameter.

Ease of Maintenance

When you can run fast and you can run dry, there is not really anything that will cause wear in the normal course of the day. Change the oil every 3000 hours and run!

BEWARE of the Copy Cats!

Since we started selling the first sanitary Twin Screw Pumps in 2003, there have been many other entrants into the market. Everyone has tried to make it cheaper. NONE have succeeded in making it BETTER!

The secret to a “TRUE TWIN SCREW” pump is the ability to dissipate the heat. For a pump to run at high speeds at constant duty, the pump must have a way to cool itself.

Some manufacturers use grease. This will never work! Most have chosen to use a hollow gear case and rely on splash lubrication. The heat will eventually catch up and destroy the longevity of these pumps.

Only a select few tout an all stainless steel, machined bearing housing. The shafts are bored through the entire housing. The area of low pressure behind the shafts causes the oil to pump back and forth through the recirculation channels to fully lubricate the bearings. This “PUMP within a PUMP” is what dissipates the heat on the pump. WATCH THIS VIDEO!