The DLM/S Mixer – THERE IS NO EQUAL!

The DLM/S Mixer has no equal! This is a big statement to back-up.

In partnership with INDAG Maschinenbau GmbH, INFINI-MIX is fast becoming the leader in dynamic, continuous mixing in North America. We pride ourselves on offering the widest range of inline mixing solutions. We can do virtually any type of mixing you can imagine, from simulating manual stirring with our delicate M series mixer, up to high shear emulsifying and homogenizing with our H series mixer.

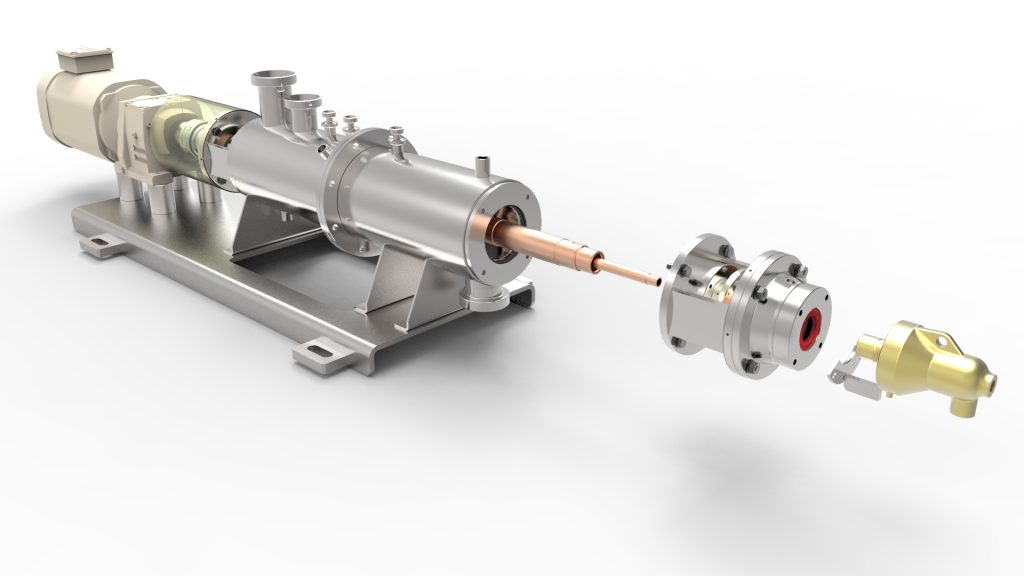

The S Series mixer is the workhorse of the product line being the only mixer on the market capable of handling the highest viscosities, the highest pressures and the highest temperatures. It has multiple configurations allowing it to be used in LIQUID-LIQUID and LIQUID-GAS mixing. What else sets the DLM/S apart from the competition?

DLM/S Mixer Advantages

- Process Pressures in Excess of 200 BAR!

- Process Temperatures in Excess of 300°C!

- Viscosities up to 10,000,000cps!

- Jacketed Housings are Standard On All Mixers

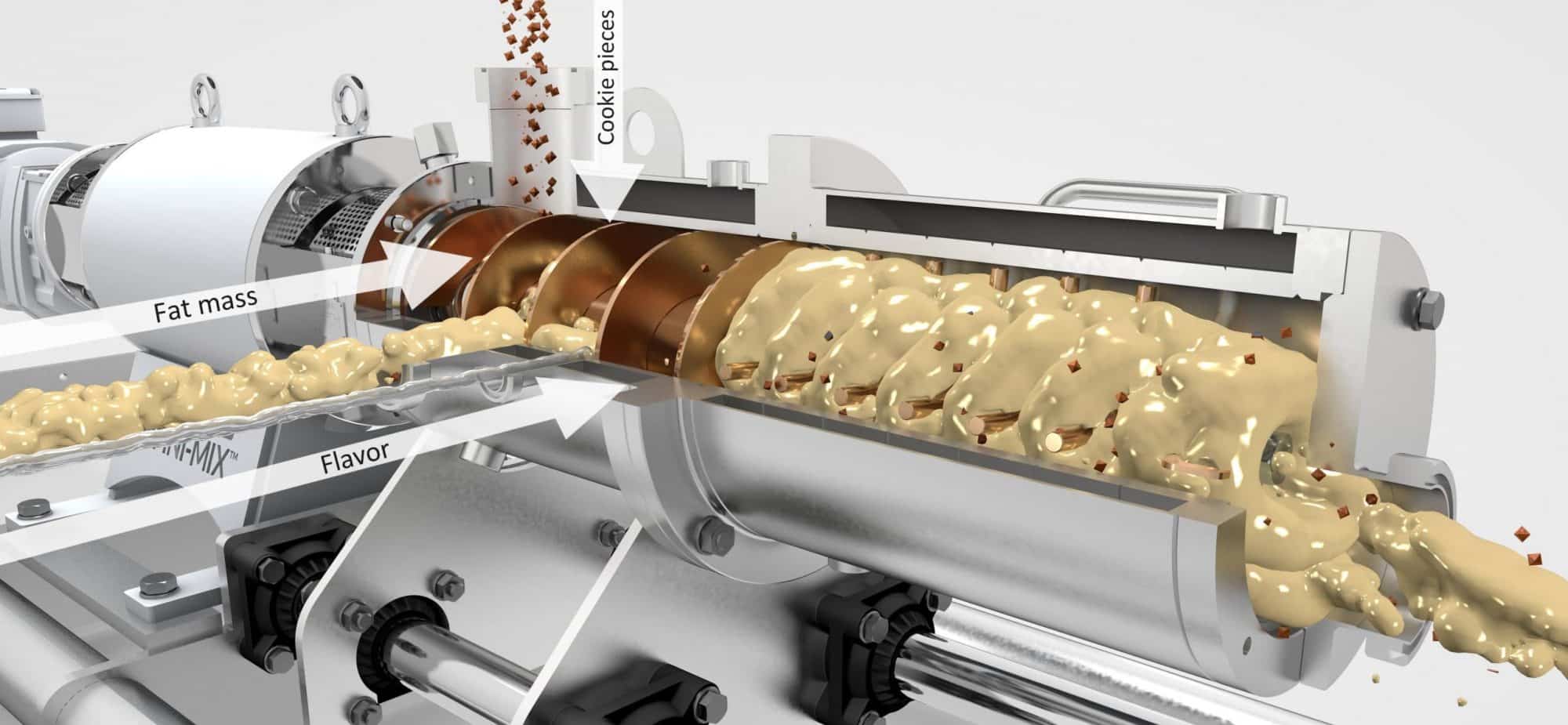

- Customizable with Multiple Inlets at Different Mixing Stages for Varying Mixing Intensity for Multiple Ingredient Streams Simultaneously.

- Temperature Controlled Rotors Offered as Option

- Teflon-Lined Wet End Available

- Wet Ends Made From Exotic Alloys Available

- Fully CIP-able and Capable of Self-Cleaning

- Commonly Used for Direct Steam Injection & Product Aeration

COMMON APPLICATIONS

LIQUID-LIQUID MIXING APPLICATIONS

We consider the DLM/S Mixer to be a “medium shear” device, imparting up to 10,000 -1/s of shear in a single pass. This is considered to be “high shear” to some of our competitors.

We have the unique ability to have multiple inlets for simultaneously dosing multiple additives or simply to have dedicated ingredient streams pre-piped to run when needed. This allows for quicker recipe changes and lower costs for cleaning in-between runs.

The jacketed housings for heating / cooling the product come standard while the temperature controlled rotor comes as an option. This is especially useful when dealing with molten candy masses or polymer blending when maintaining temperature is crucial.

STEAM INJECTION APPLICATIONS

The DLM/S series mixer offers the most efficient use of steam during the cooking process. 100% of the thermal energy is used which directly translates into less cost to the manufacturer.

Simply pump your emulsion or mixture to the mixer while the steam is regulated to the custom inlet and produce a finished, homogeneous cooked product at temperature. Our dynamic, inline mixing solution is superior to other static steam injection systems for several reason:

- The cooling jacket keeps the product from burning onto the housing, translating to virtually endless runs.

- High efficiency by instantaneously condensing of the steam into the liquid.

- Low pressure steam requirements for continuous cooking.

Processed cheese can be cooked continuously without scaling or build-up on traditional heat transfer solutions. Soups and gravies can be produced at low pressure and in a small footprint. Starches can be cooked with virtually no pressure drop across the mixer. And all mixers are fully CIP-able to making recipe changes quick and cost effective.

PRODUCT AERATION APPLICATIONS

The rotor and stator design on the S series mixer allow for consistently efficient dispersion of gasses in a liquid. Whether you are dispersing nitrogen for peanut butter; aerating fat masses, cream fillings or whipped cream with CO2 or simply injecting air into marshmallow, the DLM/S fully disperses the air into the fat mass at temperature. The jacketed housing is used to temper the product during aeration so as not to lose aeration after the product is cooled.

Controlling the back pressure on the discharge of the mixer allows for more precise control over the level of aeration. Our aeration panel allows you to dial in the level of aeration inferentially or it can be tied into your PLC for Instantaneos Feeback and control.