BUTTER & MARGARINE

Butter and margarine processing are two very different processes. Butter is a dairy-based product that involves “churning” while Margarine is oil-based and requires high shear mixing and emulsifying.

BUTTER PROCESSING

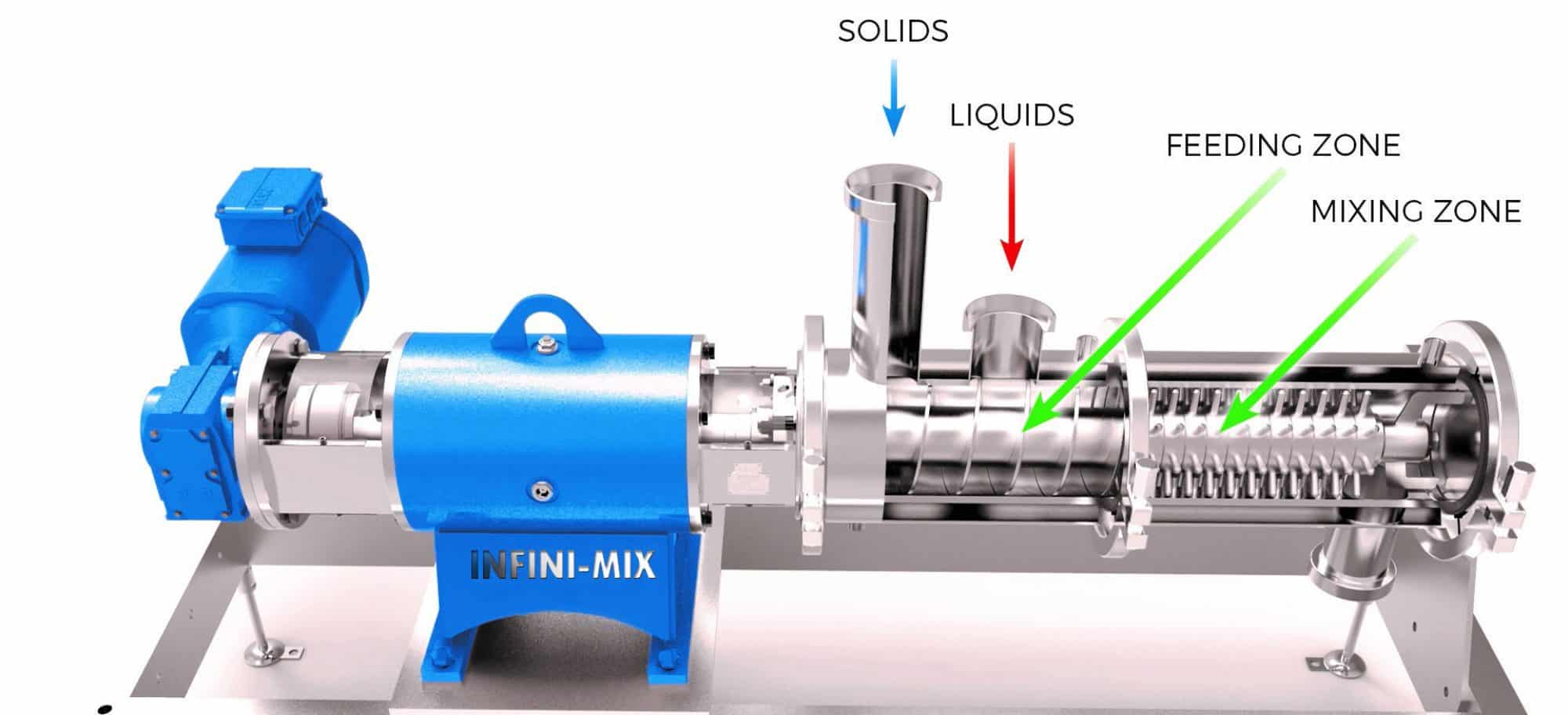

The Infini-MixerTM is commonly used for Late Stage Differentiation of finished butter products. Adding salt, seeds or flavoring can easily be done at the end of the process INLINE instead of in a batch process. This saves cleaning costs and downtime associated with changing flavors and inclusions.

MARGARINE PROCESSING

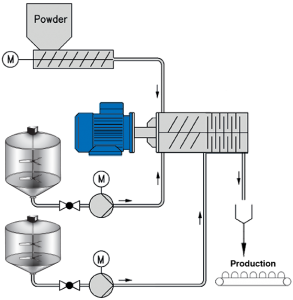

Margarine processing involves emulsifying oil blends, water, gums & thickeners and coloring & flavorings. Such emulsions require high shear forces to eliminate agglomerations fully hydrate all powders.

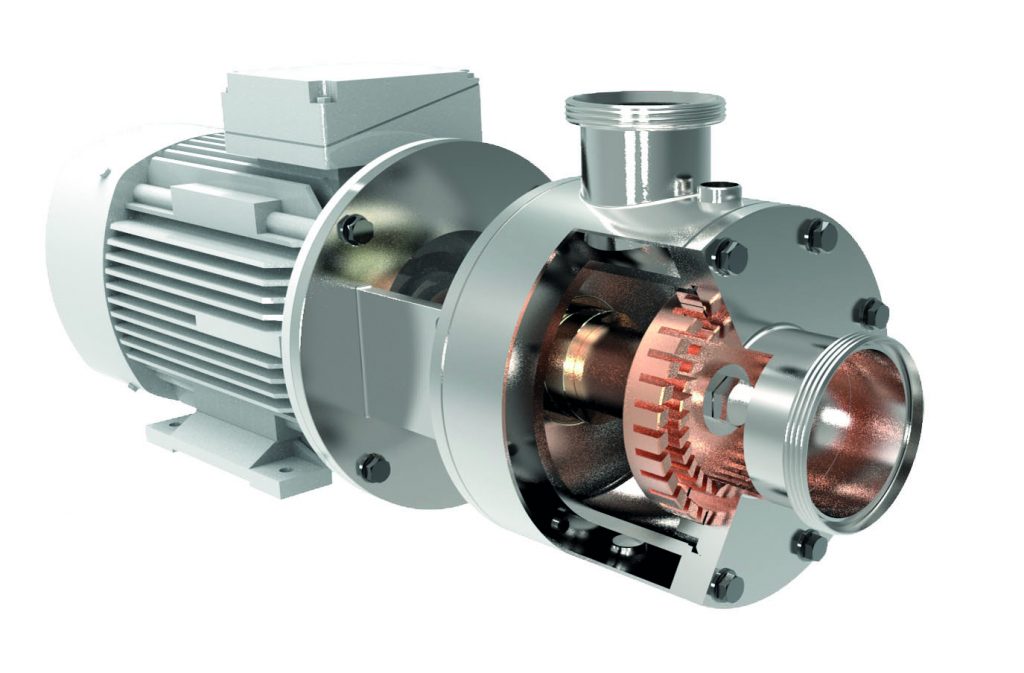

The Infini-MixTM H Series mixer is capable of creating very fine emulsions through its tight tolerances between the rotor and stator. This mixer is capable of reducing droplet sizes <6 micron!

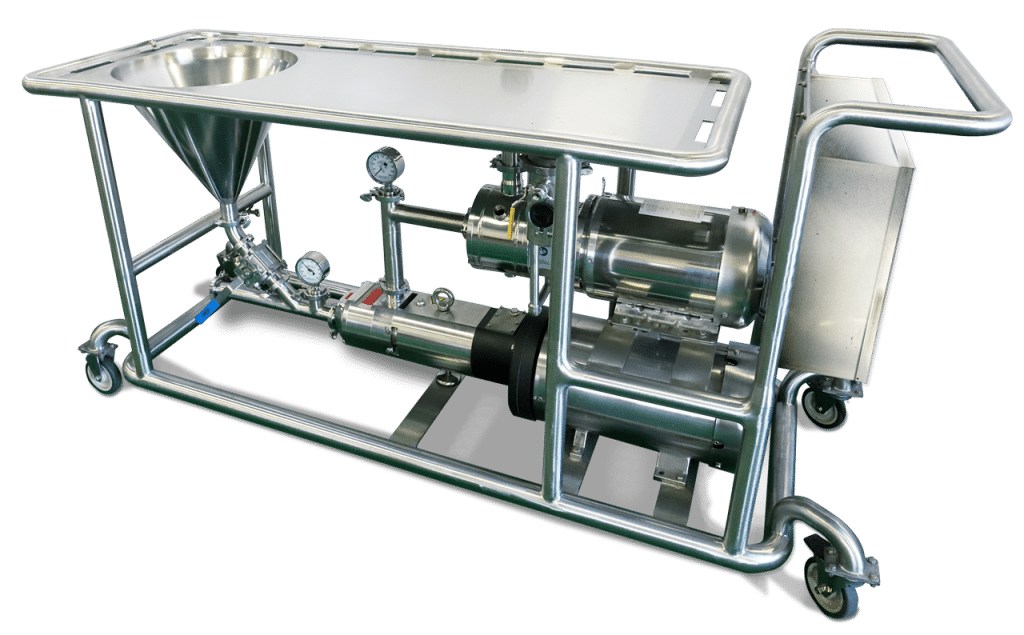

The Infini-MixTM Recirculated Batch mixer is ideal for powder and flavor addition in a batch process. Powders can be ergonomically added through the workstation hopper at operator level. The high shear capability of the the H mixer is ideal for powder & liquid addition in a single pass.