Plant-Based Substitutes

Plant-Based substitutes for meat and dairy products are quickly filling our grocery store shelves. These innovations in formulations require a wide range of mixing solutions with the full range of intensities.

Traditional meat packers are now making plant-based substitutes out of cultures and a wide range of emulsions.

Processors of dairy products that used to focus on delicate blending of cultures and inclusions are now forced to create thicker and heavier emulsions with high intensity mixing on the same equipment.

How do you select a mixing solution that can handle the full range of mixing intensities required to product both dairy and dairy substitutes?

Meat Substitutes

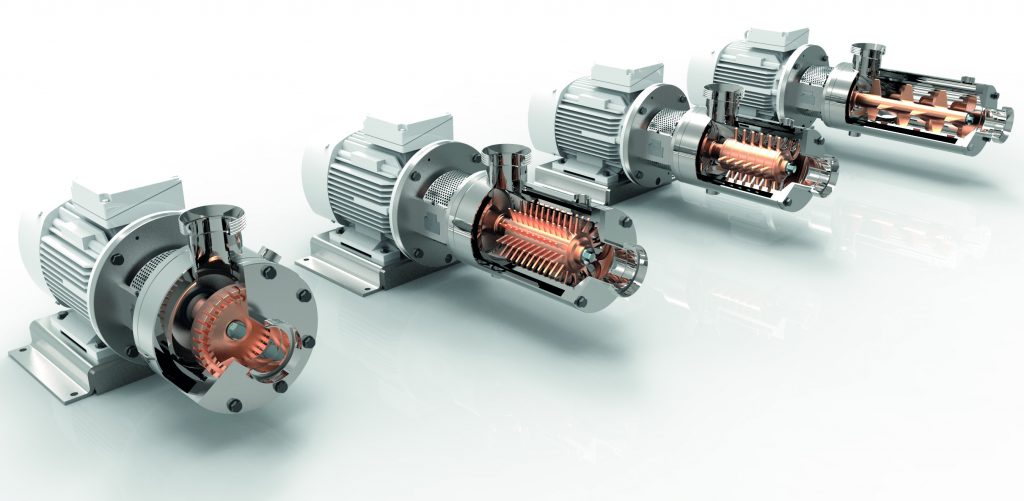

A variety of live cell cultures can be used to achieve specific flavor profiles. The DLM/M series mixer is crucial for delicate handling of these cultures at a consistent temperature to maintain a high live cell content.

After the fermentation process, multiple liquid ingredient streams are blended with medium to high intensity to create a stable emulsion and a consistent mouth feel. These applications are best suited for the DLM/S and DLM/H series mixers.

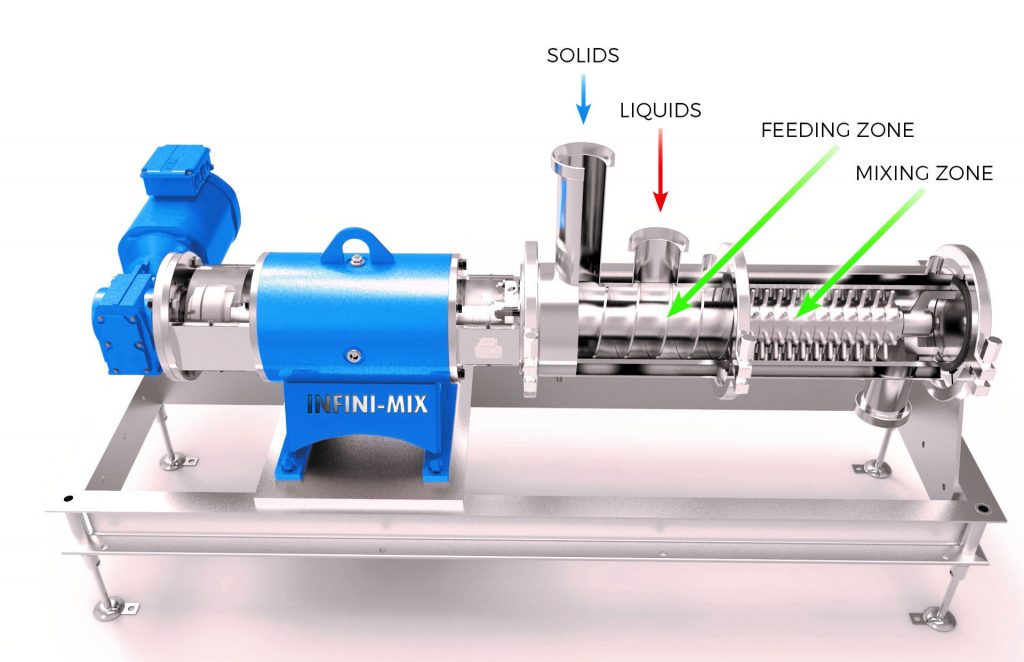

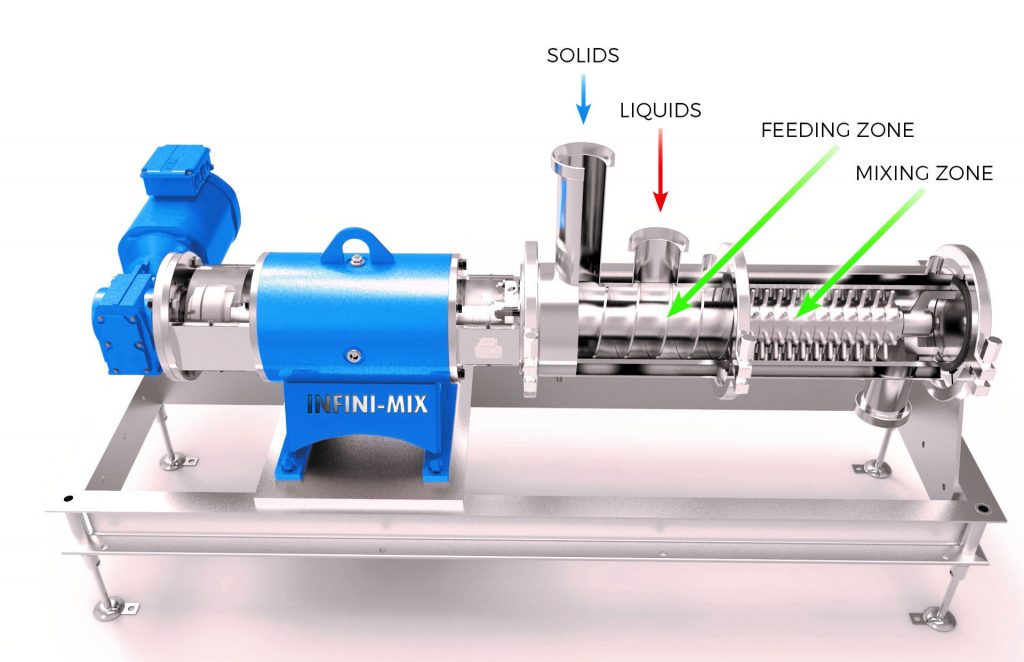

Other manufacturers blend a wide variety of dry grains with heavy emulsions but wish to keep the integrity of these solids. This is the job of the INFINI-MIXER Continuous SOLID-LIQUID Mixer.

The finished base product can be further differentiated with aromas and spice blends to create the perfect flavor profile. This is typically done with gentle mixing elements.

The INFINI-MIXER is perfect for late stage differentiation of the base product. It is delicately blends multiple solid and liquid ingredient streams while maintaining product intregrity and temperature. Recipe changes are quick with little product loss. Simply clean from the mixer forward and maintain the feed lines charged with the base product.

Dairy Substitutes

Dairy substitutes have an even wider range of mixing intensities throughout the process. Additionally, they are not just limited to LIQUID-LIQUID and SOLID-LIQUID applications.

Fluid Milk Alternatives

Fluid milk alternatives require milling and hydration. Almond, soy and oat milk utilize the gentle, long residence time of the DLM/M series mixer for softening the solids and then use the high shear milling capabilities of the DLM/H series mixer for particle reduction to allow for greater surface area to hydrate faster.

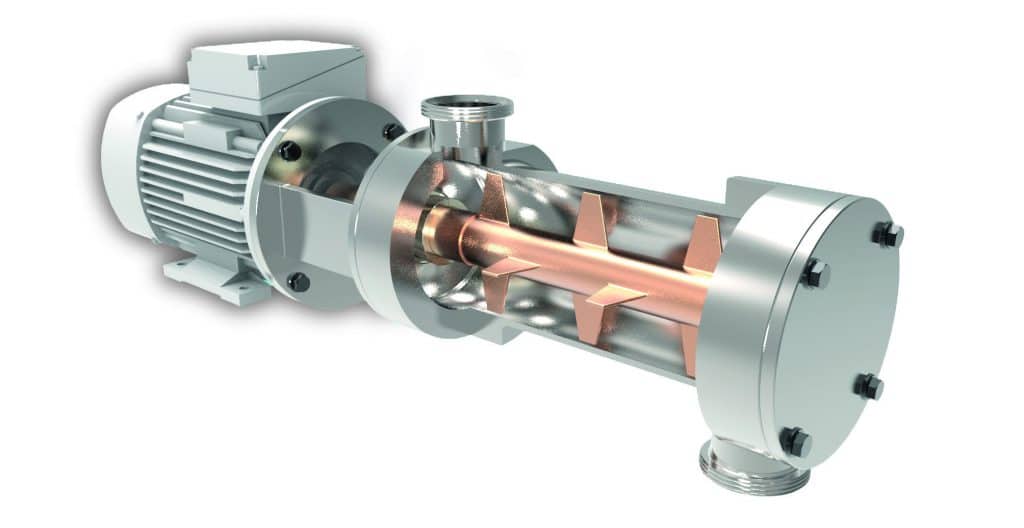

The LG-S mixer is also used for injecting steam into a slurry of solids the hasten the hydration process. This mixer has the most efficient use of the thermal energy by fully dispersing the steam.

The DLM/M series mixer is also used for blending in flavorings to the finished base product.

Ice Cream Alternatives

Ice cream substitutes use thicker, heavier emulsions with high mixing intensity requirements to create a stable product. This is best performed by the DLM/S series mixer.

The INFINI-MIXER is the best mixer for blending multiple streams for solids and liquids simultaneously. This can be flavorings or inclusions in excess of 60% solids. This is far higher than what our competitors can offer.

Yogurt, Cream Cheese & Other Cultured Alternatives

These plant-based alternatives typically require much more intensive mixing (DLM/S mixer) for the base product and then much less intensive mixing of any differentiating ingredients. Delicately blending fruit and flavorings into dairy-free yogurt and cream cheese spreads with the DLM/M series mixer is the lowest cost with the least amount of product loss on flavor changes. There is never streaking and product integrity is higher than any alternative.

The INFINI-MIXER Continuous Solid-Liquid Mixer is ideal for late stage differentiation of the base product. It is used to vary spice blends, liquid or powdered flavorings and even large inclusions while maintaining product temperature. Recipe changes are quick with little product loss. Simply clean from the mixer forward and maintain the base product lines charged.

CLEANABILITY

One of our biggest benefits is the cleanability of all of our mixers. This is paramount for those manufacturing facilities that run both Dairy and Dairy-free on the same equipment. All mixers are fully CIP-able.

FROM CONCEPT TO REALITY

Our Pilot Plant and fleet of trial equipment provide our customers with an opportunity to develop their process with confidence. All pilot equipment is fully scaleable to production size.

We offer our mixers as well as most ancillary equipment required to demonstrate proof of concept for any of our mixing solutions.