PREPARED FOODS

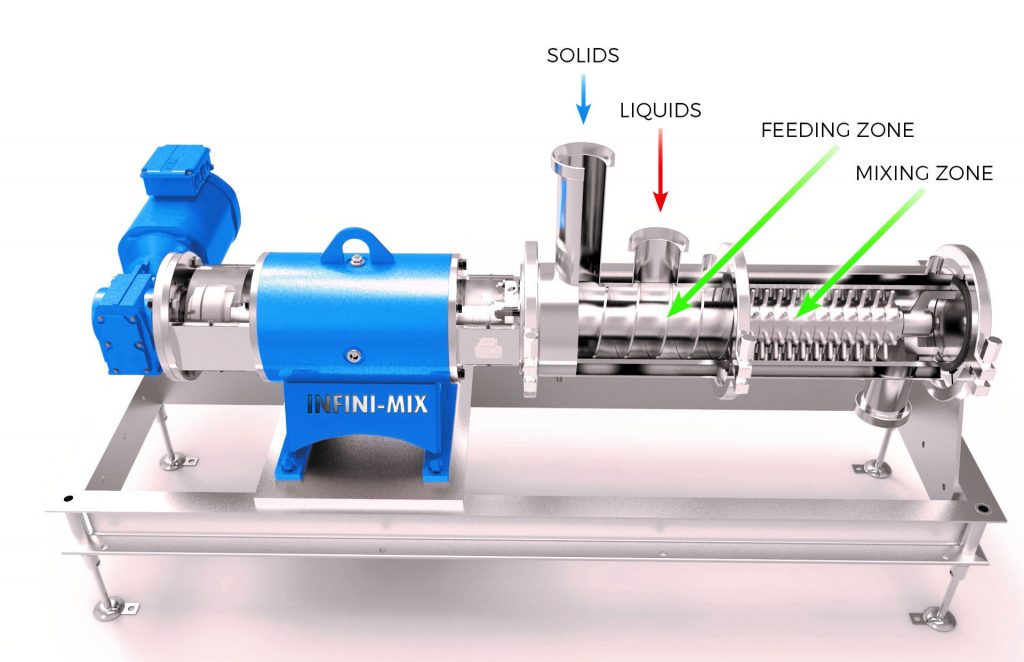

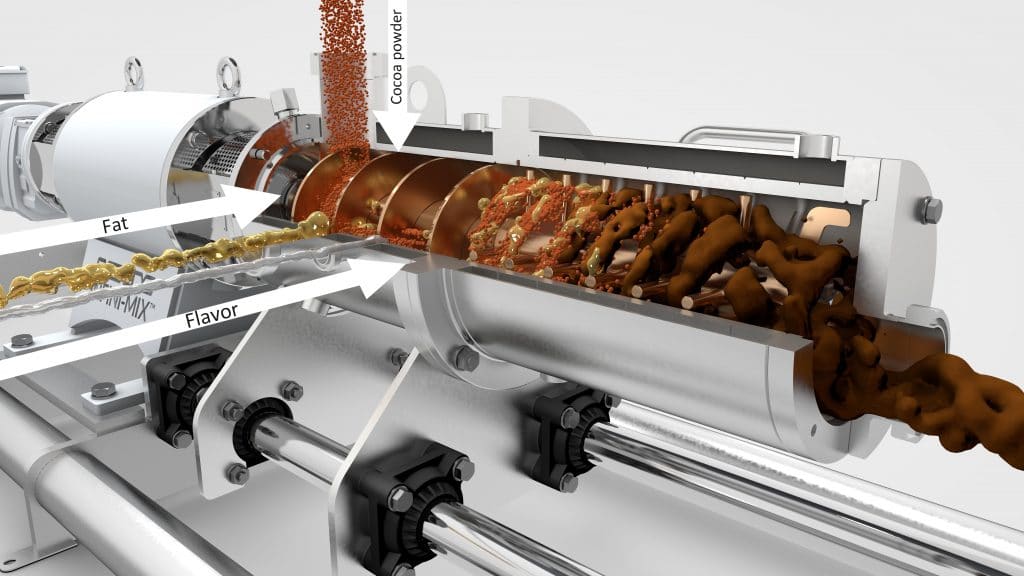

The Infini-MixerTM is ideal for blending delicate solids into prepared foods. Solid and Liquid ingredient streams are metered directly into the FEED CHAMBER at the appropriate ratios. The combined ingredients are gently conveyed through to the MIXING CHAMBER for the perfect mixing result.

SOLUTION #1

LARGE DELICATE SOLIDS: Mac & Cheese

A customer making Macaroni & Cheese was blending the cheese sauce with the pasta in a vessel prior to packaging. The pasta is “blanched”, or partially cooked, prior to being blended with the hot cheese sauce. If ever the depositor went down for any reason, this would leave the pasta “cooking” in the sauce. It did not take long for the pasta to become too soft and the product would be dumped.

The Infini-MixerTM installed at the very end of the process above the depositor allowed for a “just-in-time” blend as the depositor called for the finished product. This greatly reduced product losses.

SOLUTION #2

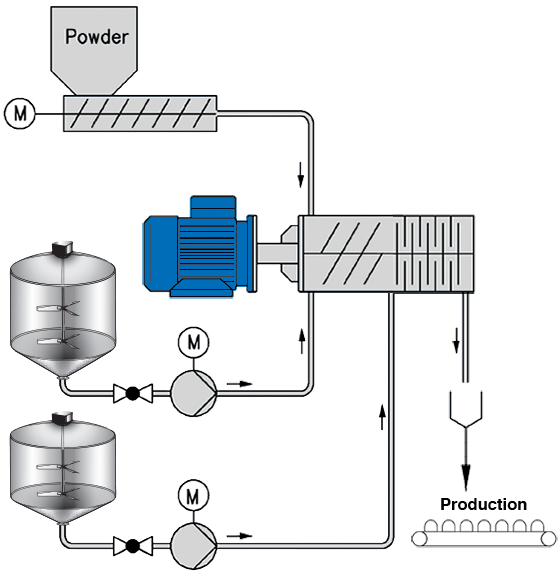

LATE STAGE DIFFERENTIATION - Flavored Applesauce

A customer makes plain applesauce 75% of the time. However, their flavored applesauces are gaining popularity. They have an apple & cinnamon flavored recipe and a strawberry-apple recipe and creating more all of the time. The problem is that it takes them an entire shift to clean these flavors and essences out of the batch tanks and the process lines. This greatly hurts plant efficiencies.

The customer is able to take advantage of Late Stage Differentiation by installing the Infini-MixerTM at the end of the process. The plain applesauce goes directly to the filler. When a recipe requiring a special flavoring needs to run, a valve diverts the applesauce supply to the The Infini-MixerTM where the appropriate flavoring is metered into the sauce. When the flavor run is over, the valve is turned back to divert around the mixer and they are back to the plain product. The only thing that needs to be cleaned is the mixer. Problem solved!