DRESSINGS, SAUCES & DIPS

EXAMPLE #1

Queso / Nacho Cheese Dip, WITH or WITHOUT Inclusions

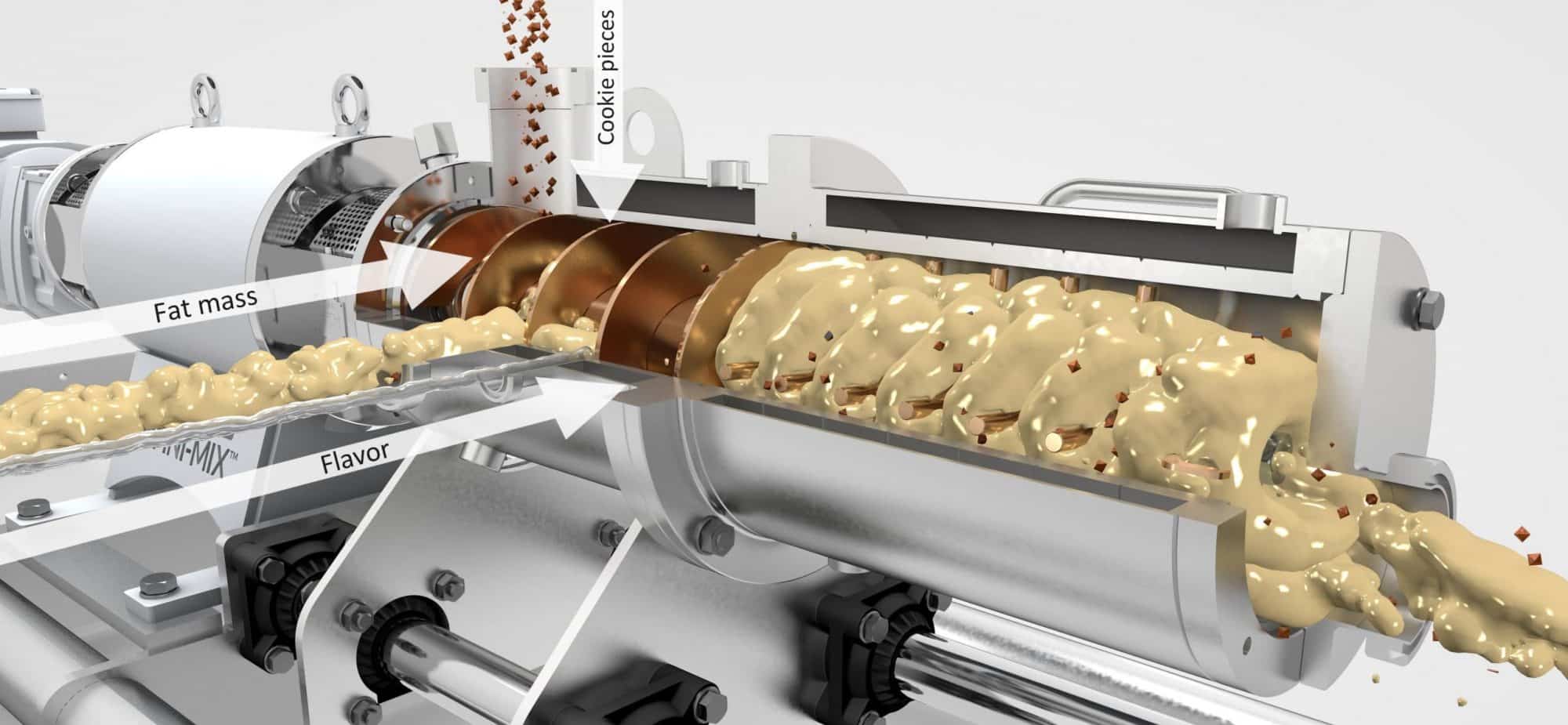

The Infini-Mix S-LG Mixer provides a high level of emulsifying shear and dispersion of steam in a continuous processed cheese process. Steam is injected directly into the mixer. The mixing elements continuous blend the ingredients and disperse the steam to cook all of the powders thoroughly and homogeneously.

There is never fouling inside the mixer and the process is fully CIP-able. This allows for longer runs and significant savings for less frequent CIP cycles.

The Infini-Mix N Series Mixer can be used for delicately blending pepper slurries directly into the process cheese stream. The Infini-MixerTM can be used to blend chorizo, ground meat or even spice blends.

EXAMPLE #2

SALAD DRESSINGS

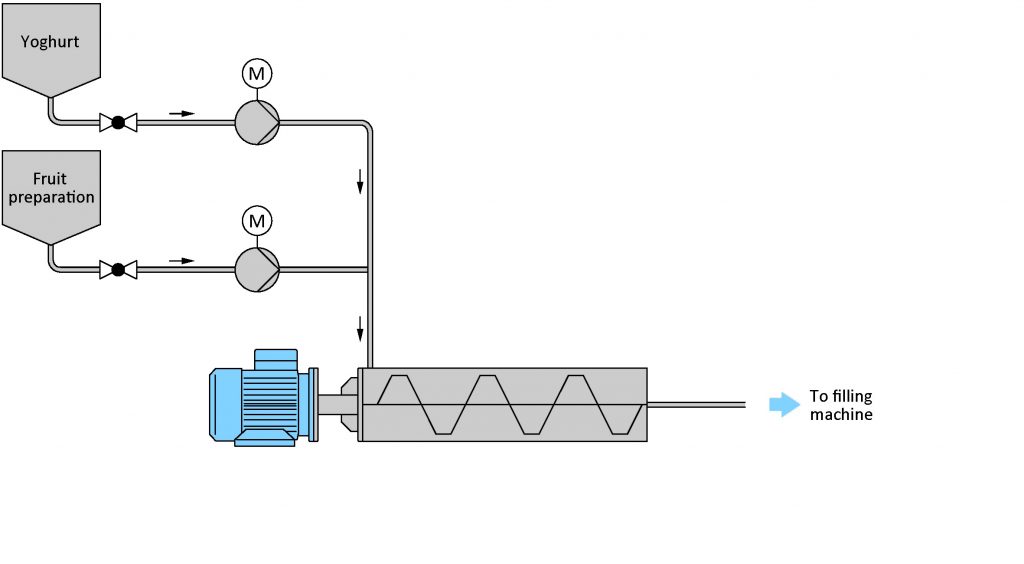

Salad dressings are typically done in a batch-type process. All ingredients are metered (or pre-weighed) into the batch tank. In addition to spice blends, there are a variety of solid/powder ingredients like gums, thickeners and flavorings must be hydrated. In a batch tank, solids can stick to the sides and never be fully wetted out. The batch process also typically takes a great deal of manual labor.

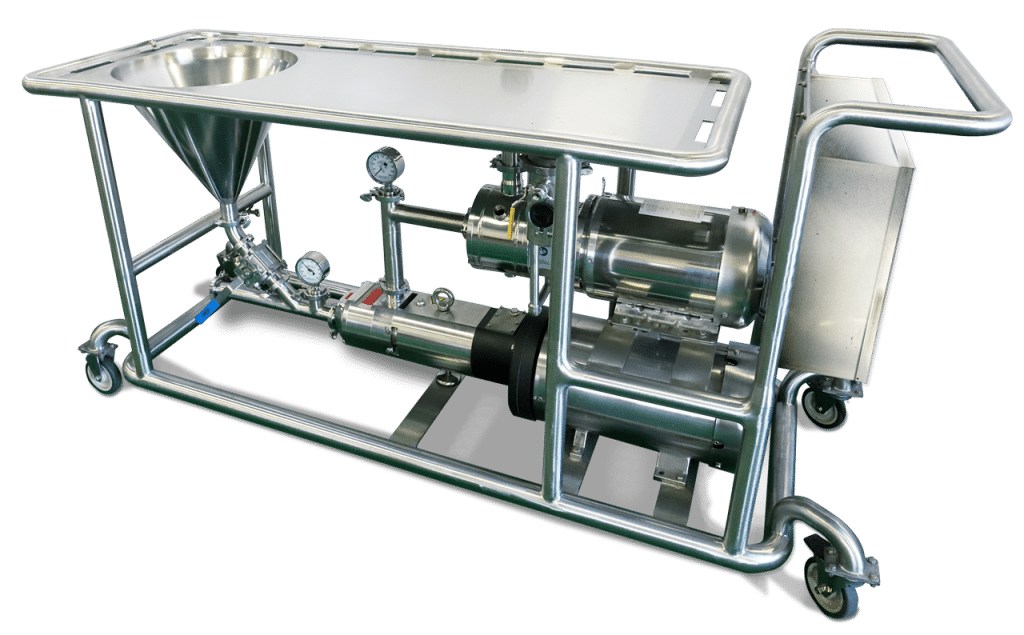

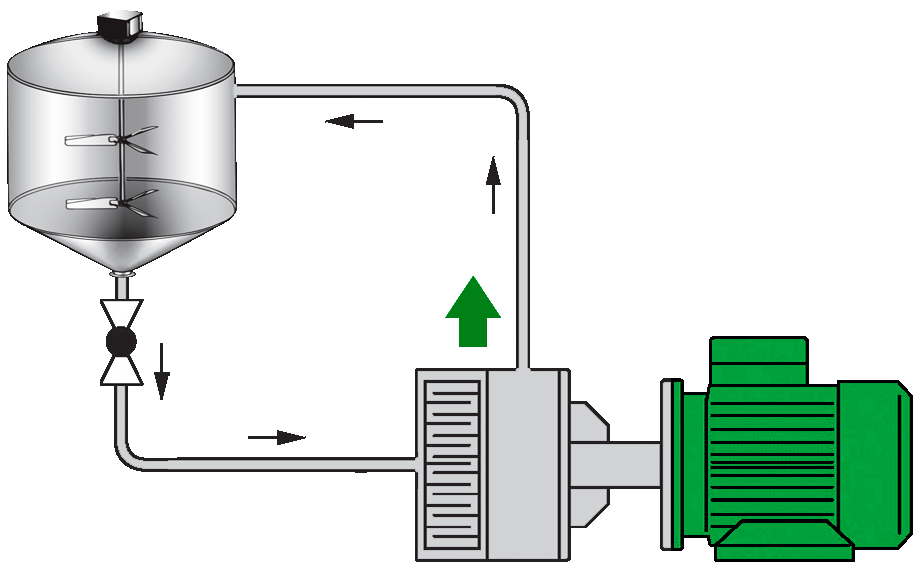

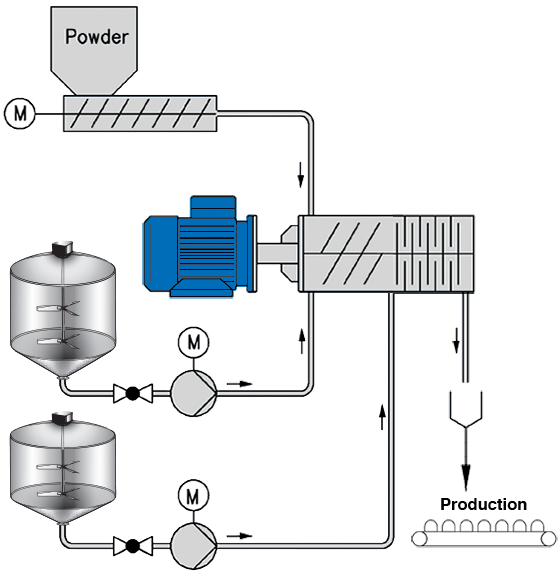

The Infini-MixTM Recirculated Batch Mixer (or RBM) sits beside the batch tank and pulls the solids into the liquid stream from the batch tank and recirculates the blended product back to the vessel. It has the ability to suck powders into a thick stream of liquid and at high pressures. This eliminates the need for a person to carry solid ingredients to the top of the tank and drop it in.

Additionally, everything that exits the tank is guaranteed to go through the inline mixer on the Infini-MixTM Recirculated RBM. This eliminates the need for strainers downstream to catch unmixed dry ingredients.

EXAMPLE #3

Adding Delicate Inclusions to Mayonnaise & Dressing Bases

Adding relish to a mayonnaise for a tartar sauce or adding blue cheese crumbles to a dressing base are all applications where a manufacturer is trying to maintain large solids integrity in a delicate emulsion. The Infini-MixerTM delicate blends solids into a liquid stream at the end of the process.

A large salad dressing manufacturer installed a small mixer and injection skid prior to the filler. For those products which require a delicate inclusion, the flow from the batch vessel is diverted through the mixer where the inclusions are delicately blended into the base prior to the filler bowl. When the run is complete, the mixer is valved off and cleaned in a separate CIP circuit in order to minimize recipe changeovers at the filler.