DAIRY

The Infini-MixerTM is ideal for delicately mixing inclusions and flavoring into virtually any dairy product. Inclusions can be fruit findbride comments pieces, spice blends or flavor slurries. Many manufacturers will use a batch process to mix the inclusions into the finished product. This can sometimes reduce the viscosity of the base product. When the recipe changes to a different inclusion, the batching vessel and all of the transfer piping and equipment must be cleaned.

EXAMPLE #1

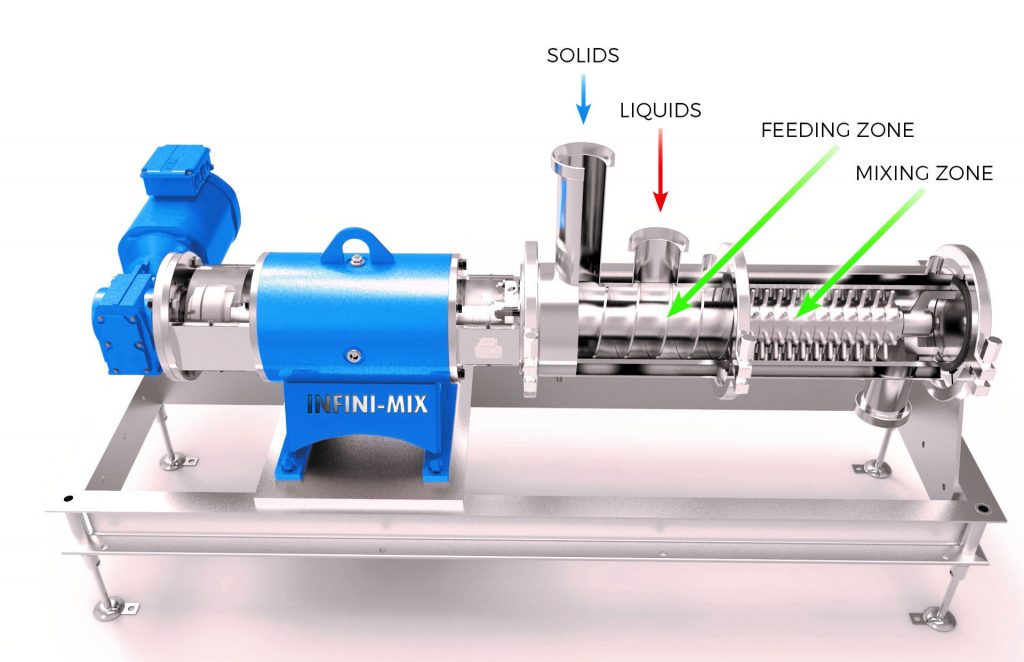

Instead, the Infini-MixerTM is installed at the end of the process, just prior to the depositor. The base sour cream is metered into the liquid ingredient port on the feed zone while using a gravimetric solids feeder meters the spice blend directly into the solids port. While delicately blending the solids the jacketed housing and temperature controlled rotor tempers the product to ensure a consistent temperature through out the process.

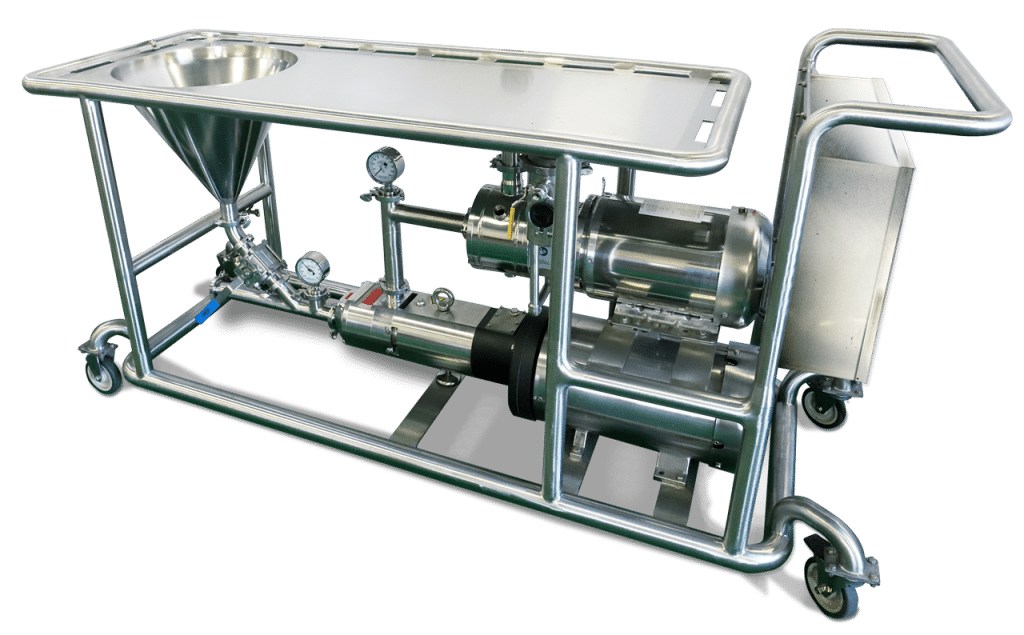

When the recipe run is complete, production go right back to running plain sour cream by bypassing around the mixer. The mixer can be CIP’ed by itself by using isolation and mix proof valves or it can be cleaned by hand.

Take a customer who is making sour cream-based dips. They make sour cream all day but once a week they need to make a batch of sour cream and mix in a spice blend in a batch vessel. After the batch, the vessel and the entire process that came in contact with the product must go through a CIP cycle. This adds costs for cleaning (chemicals, water, etc.) as well as downtime and labor.

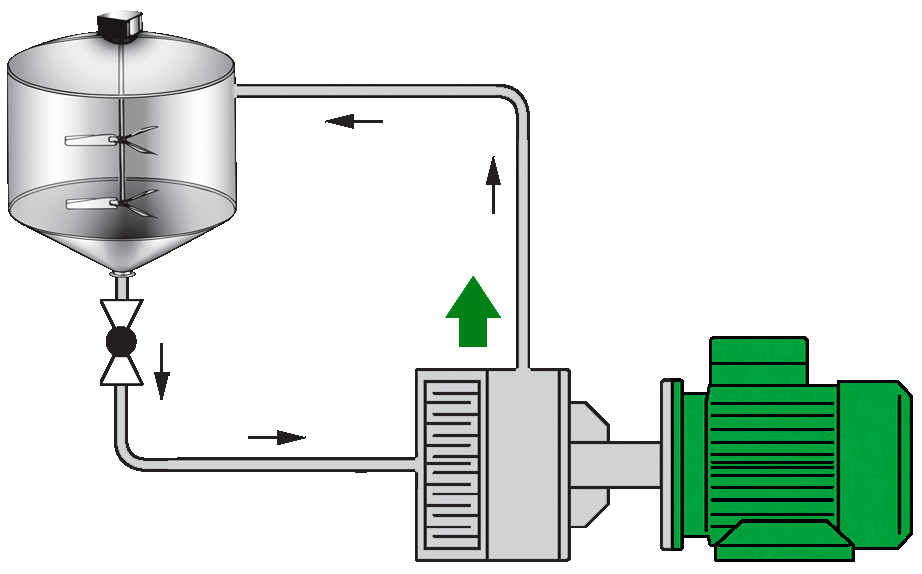

Dairy products with flavoring and inclusions like chocolate milks and smoothies, can blend the differentiating ingredients just prior to the pasteurizer, saving time and cleaning costs to use a batch tank. Flavored cream cheeses and butter blends with seasonal spices can also utilize the late stage differentiation process to minimize costs from changeovers.

EXAMPLE #2

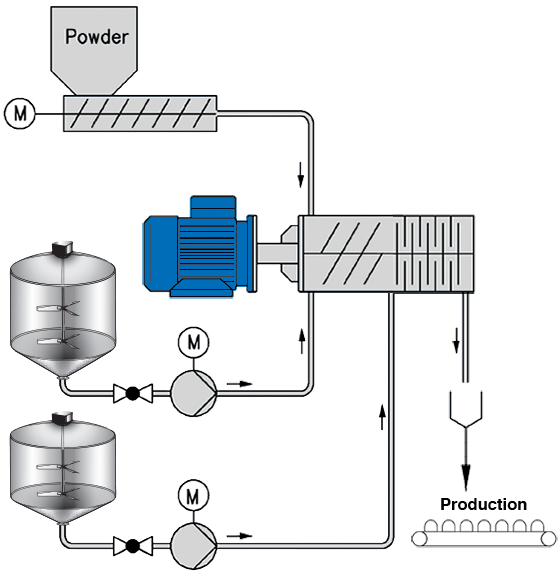

Many manufacturers commonly add flavor powders and coloring to the milk in a batch tank. These powders can be sticky. In a batch tank, they can stick to the sides and there is also no guarantee that all powders will be fully wetted in the workhead of the batch mixer.

Many manufacturers commonly add flavor powders and coloring to the milk in a batch tank. These powders can be sticky. In a batch tank, they can stick to the sides and there is also no guarantee that all powders will be fully wetted in the workhead of the batch mixer.