Liquid-Gas Mixers

The INFINI-MIX Advantage in LIQUID - GAS Mixing

All INFINI-MIX Dynamic Mixers come standard with a jacketed housing. This is a tremendous benefit when blending gases with liquids.

When dispersing steam in a liquid, some products have the tendency to BURN onto the housing of the pipe or tank or even a steam injection valve. The jacketed housing on the INFINI-MIXERS allows us to cool the product contact surfaces while cooking the product. The result: NO BURN ON — EVER!

When dispersing a gas to aerate a product, you want to aerate as close to the packaging temperature as possible. If you aerate when the product is hot, the air bubbles will be larger. As it cools, the bubbles will become smaller and smaller. The jacketed housing on the INFINI-MIXERS allow us to temper the product as we aerate to keep the product as close to the packaging temperature as possible.

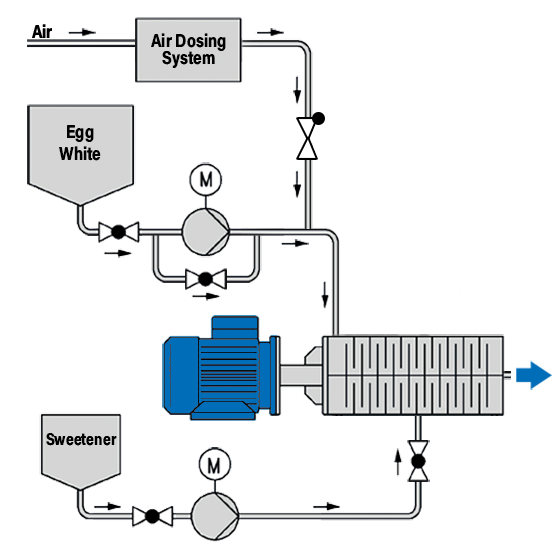

Infini-Mix™ offers Liquid-Gas Mixers for blending multiple ingredient streams simultaneously. Liquid + Gas mixing is a specialized field. It can involve using steam to cook a product continuously (inline) as well as aerating a fat mass with CO2 or nitrogen to create form and structure. The Infini-Mix™ LG Series mixers are capable of handling these wide ranging applications and our systems group packages the ancillary equipment for turnkey solutions.

Gases are injected directly into the mixer either inferentially with a hand valve or metered with control valves and/or flowmeters. The liquid ingredients are metered in with a pump and/or flowmeter. The rotor disperses the gas throughout the liquid for even distribution.

All Infini-Mix™ Liquid-Gas Mixers have the ability to receive multiple ingredient streams. Multiple ports can be placed anywhere along the housing. This allows for different ingredients to receive different levels of residence time. For example, a cake frosting can receive the white icing base with the nitrogen at the front of the mixer while the coloring is injected midway through the mixer.