Dynamic Mixers – Direct Steam Injection

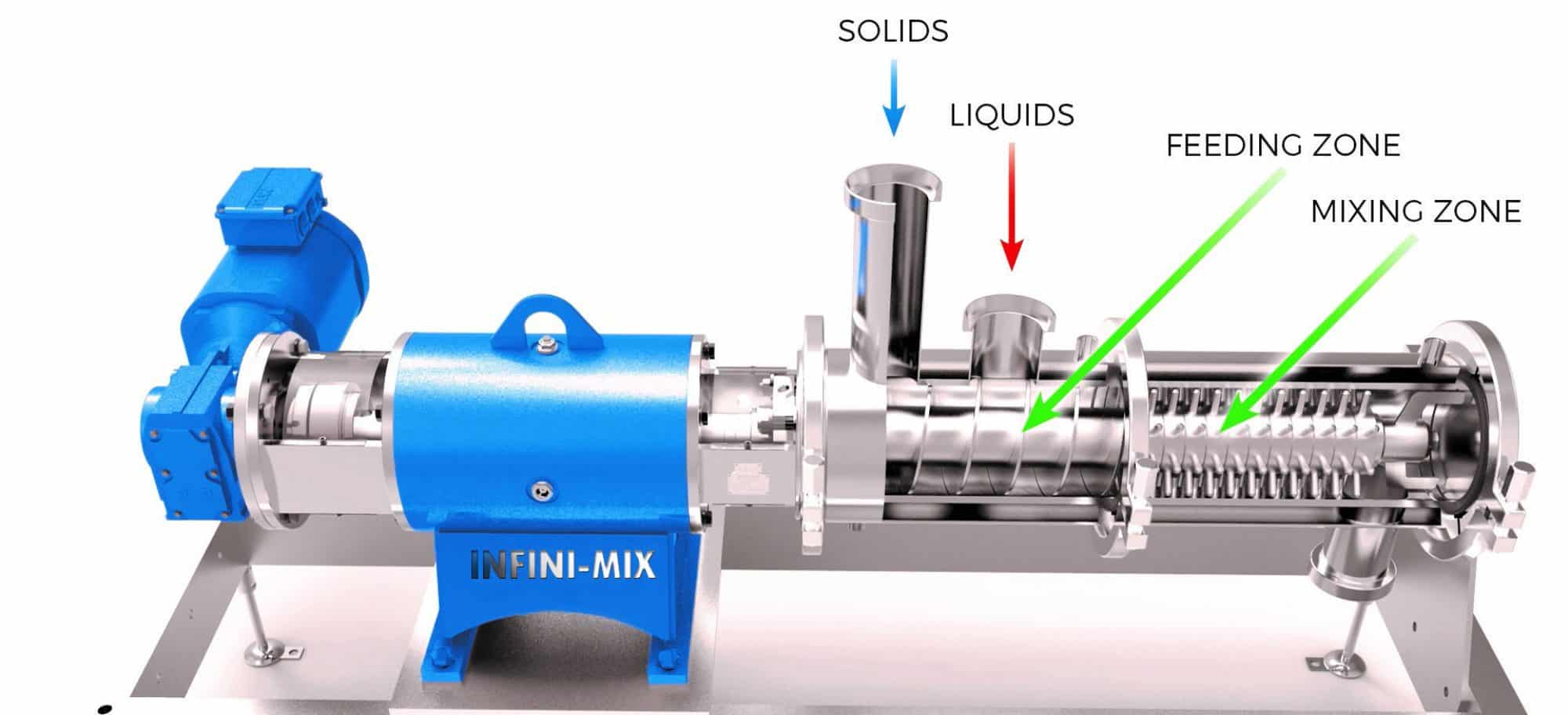

An INLINE DYNAMIC MIXER that can fully disperse steam and throughly cook a product is both highly efficient and requires a small footprint. Using 100% of the thermal properties of a low pressure steam and the condensing water to reduce water usage makes the switch to a dynamic mixing solution an easy payback.

When thinking about inline mixers, most people think of vigorously mixing liquids or dispersing powders into a liquid. However, an INLINE DYNAMIC MIXER that is capable of fully dispersing steam is a game changer for the food processing industry.

The most common way to cook prepared foods has been in a steam-jacketed kettle. These kettles can have a variety of agitation to maintain product integrity and to scrape the side wall. However, this type of cooking method is incredibly inefficient due to the lack of surface area and the constant issue with product burning on the sidewalls of the kettle.

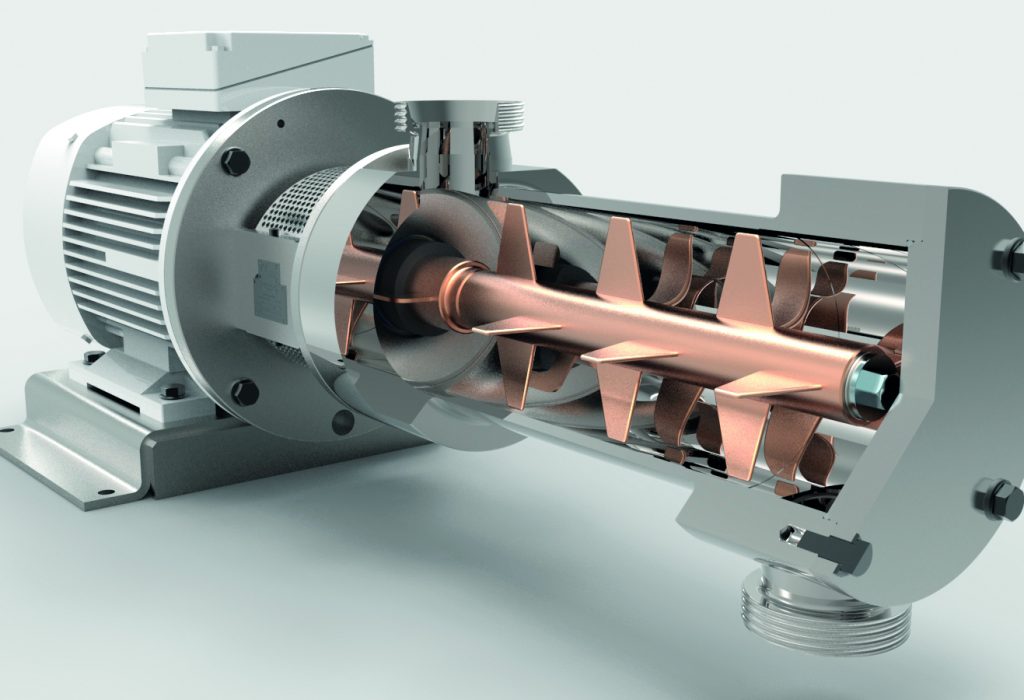

Cooking with direct steam injection is far more efficient and is not new. It has been most popularized by companies using a steam control valve combined with a sparger and/or static mixing element(s). These “mixing valve” solutions are not as versatile as utilizing an INLINE DYNAMIC MIXER. A dynamic mixer that fully disperses the steam throughout a given product has a great many benefits over both of these other methods.

Why Dynamic Mixing is Superior

Ideal for cooking continuously with steam, The S Series and the M Series Steam Cookers take a direct steam input along with the product to cook inline. Unlike scrape surface and multi-tube heat exchangers that get build-up and can foul, the Infini-Mix™ Steam mixers are fully CIP-able and can run for multiple shifts before requiring a CIP.

Infini-Mix™ Steam Mixers come standard with a jacketed housing. Cooling water is run through the jacket during operation to ensure that there is no “burn-on”.

Comparing a steam injection mixing valve to a dynamic mixer is like comparing a STATIC mixer to a DYNAMIC mixer. Static mixers are designed for s specific flow rate at a specific viscosity for a given product. Once installed, they cannot be changed. Due to the pressure drop, higher pressure and higher velocity steam is typically required.

A dynamic mixing solution has far greater flexibility due to the ability to vary the rotor speeds and flow rates. Additionally, a DYNAMIC STEAM INJECTION solution has the following capabilities:

- The ability to cook fluids with delicate inclusions like vegetables and chunks of meat without degradation.

- No “burn on” or build-up which allows for long, continuous product runs.

- Inline dynamic mixers are the most efficient use of steam as it uses 100% of the thermal properties of the steam.

- Taking advantage of the water from the condensing steam allows you to adjust the recipe to use up to 12% less water.

- Dynamic mixers do not rely on high velocity steam to do the mixing. The dynamic mixing elements fully disperse the steam and can use lower pressure and lower velocity steam. This can result in a big energy savings!

- Offer a wider range of products, viscosities and flow rates with the same mixing unit because of the ability too vary speeds and residence time.

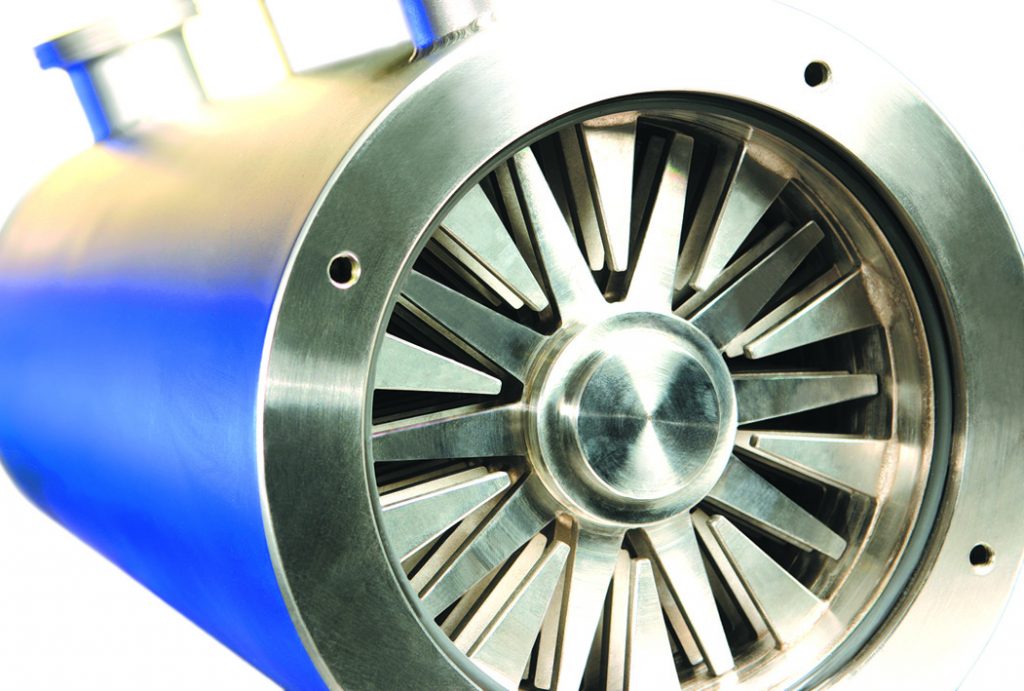

The INFINI-MIX Dynamic Mixing solutions are unique because of the wide range of mixing elements to select from. The M series mixing elements are the most gentle and can simulate the stirring of a kettle or even a large pot on your own stove. This can delicately pass large solids while thoroughly cooking the base liquid and the inclusions. These are ideal for prepared foods, soups and more delicate starches.

Common Applications

When using a dynamic mixer for cooking processed cheese, customers were able to reduce the amount of salt required because of more intensive mixing. More expensive cheese powders were able to be replaced with less expensive milk powders without any loss of taste and mouth feel. More importantly, there is NO BURN-ON of the product which allows for longer, continuous product runs. Our dynamic steam mixers come standard with a jacketed housing to temper the inlet of the mixer to avoid the burn-on issue altogether.

Fully hydrate starches for sauces and puddings without fish eyes and without damaging the gelling process. Our inline designs offer DELICATE DYNAMIC MIXING to maintain the integrity of inclusions like tapioca balls, coconut and rice. Cook soups and prepared foods while maintaining high large particulate integrity with meat and vegetables. Do all of this utilizing lower pressure steam and in a single pass.