Welcome to INFINI-MIX!

Welcome to INFINI-MIX Continuous Inline Dynamic Mixers!

INFINI-MIX does any type of INLINE mixing you can think of: LIQUID-LIQUID, SOLID-LIQUID and LIQUID-GAS. We can also create virtually any level of mixing intensity you need. From extremely delicate and simulating manual stirring all the way up to high shear homogenizing and emulsifying, we have the widest range of inline mixing solutions. We are your 1-stop shop for all inline mixing!

SO, What Type of Mixing Are You Interested In?

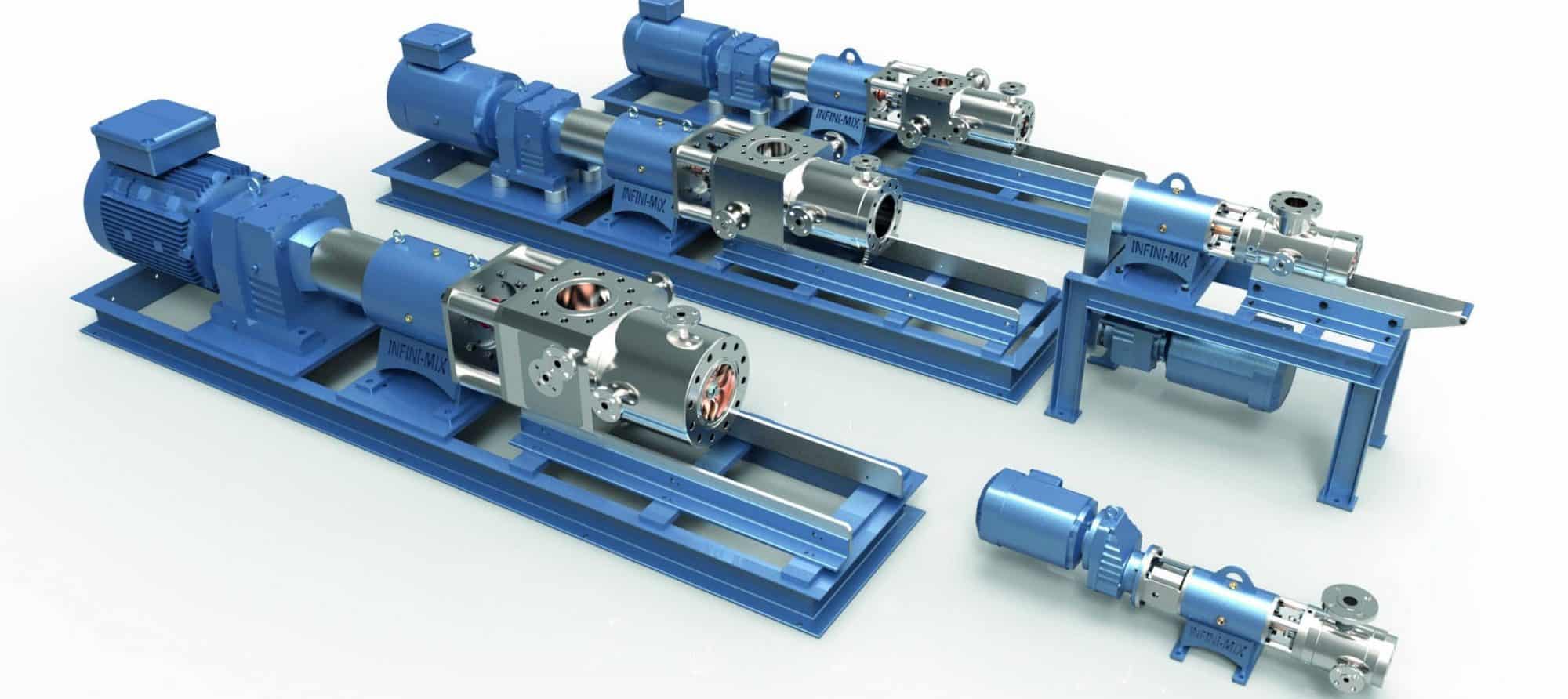

We are transforming the mixing industry with the INFINI-MIX™ Series of Continuous Inline Dynamic Mixers and Systems Solutions. In partnership with INDAG Maschinenbau GmbH, INFINI-MIX™ now offers the most complete offering of any mixer company in North America.

INFINI-MIX™ is bringing to the market a new concept that we like to call Infinite Mixing Technology. Our mixers can blend solids, liquids and/or gasses inline and at any level of mixing intensity. When you have this technology at your finger tips, we can convert virtually any process from a batch process to a continuous process. This allows our customers to run indefinitely, with the only limitation being the amount of ingredients they have on-hand. This is INFINI-MIX™’s Infinite Mixing Technology and is how we are now setting the New Benchmark in Continuous Mixing and Blending Technology.

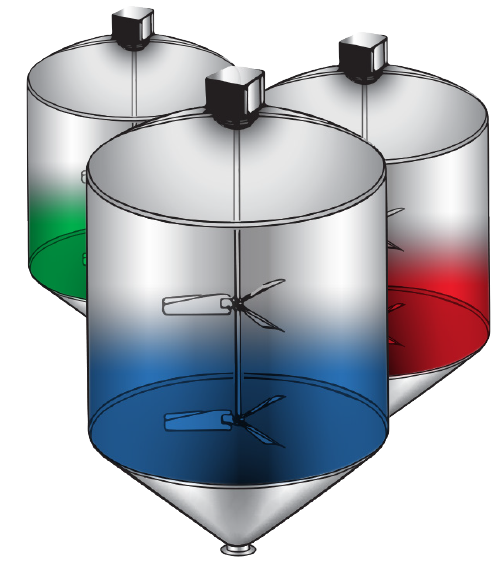

The Benefits of IN-LINE over IN-TANK

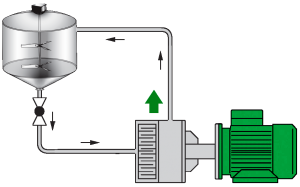

Infini-Mix™ only does Dynamic, INLINE MIXERS. Unlike an IN-TANK mixer, an inline mixer is located outside of a vessel (or group of vessels). The contents of the tank are either recirculated through the mixer or can be sized for a single pass duty. This approach to batch mixing is far superior to in-tank mixer. Click here for more details.

"DYNAMIC" Dominates "STATIC" Mixing

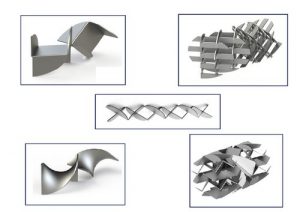

“DYNAMIC” means that there is always a rotating element that is creating the mixing energy. A “STATIC” mixer is custom fabricated for a specific application. It is fitted inside a length of pipe and there are no moving parts. The insert is cut, bent and twisted into specific, engineered patterns in order to create the desired mixing result. Find out why DYNAMIC mixers dominate.

Common Continuous Inline Dynamic Mixer Applications

Through INDAG Maschinenbau, GmbH, INFINI-MIX offers the widest range of Dynamic, Inline Mixing Solutions. We are part of a worldwide network of companies that work daily in every industry and we share our common mixing applications, our experiences and our successes.

HYGIENIC – These are sanitary applications for the Food, Beverage, Cosmetics, Personal Care and Pharmaceutical industries. Anything that is manufactured that goes on or in a living person or a pet is found in this section. This would include detergents and cleaning products.

CHEMICAL – These are applications in industries such as paints, pigments, coatings, rubber, latex, polymers, battery technologies, adhesives and biodiesel. These applications are more challenging with higher pressures, temperatures and viscosities.

ENVIRONMENTAL – These applications are primarily focused on the plastics industry and waste water processing industry.